Fuel oil filter change leads to generator failure

Comments:

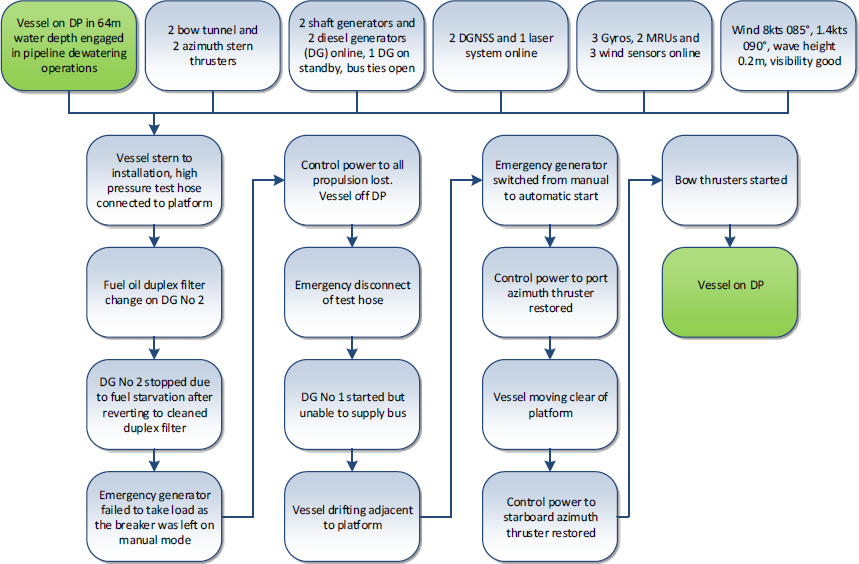

During ‘routine’ rounds the engine room watchkeeper decided to replace the left filter of the duplex fuel oil filter of DG No 2. This generator was part of the port redundant system and supplied power to the 415v and 220v bus A and emergency switchboards. DG No 2 suffered a blackout due to FO starvation after the filter was changed and as a consequence of incorrect operation of the duplex fuel filter. DG No 1, which is also part of the port redundant group, was started, however it was unable to supply power to the bus. The emergency generator did not connect to the bus bar as the breaker was left in manual mode therefore losing power to bus A and the emergency bus bar.

At this juncture batteries should take the load for control power of DP essential equipment, however the batteries were drained.

The failure of the port redundant group should not have resulted in the loss of all propulsion control power as there was no failure on the starboard redundant group. However, this was not the case because there was a design fault such that the 220v AC and 24v DC systems providing control power for all propulsion was from the port redundant group only.

The vessel is five years old and this design fault was not captured in the FMEA or annual DP trials. The last annual

DP trials was conducted less than three weeks prior to the incident.

The principle corrective actions initiated were:

- No maintenance to be undertaken on any active or passive DP component whilst working within the 500m zone of an installation.

- Switchboard setup was permanently modified so that propulsion control power was supplied from different redundant groups.

- Switchboard setup to be verified by two separate watchkeepers.

- Regular DP blackout drills to be instigated.

- Regular switchboard setup training to be conducted.

- Battery checks and testing routines improved.

- Company test and trials programmes reviewed and updated.

Considerations from the above event:

- This incident again stresses the need for a good initial FMEA, tracking of modifications and ensuring documentation is up to date, plus the importance of proving redundancy groups on a frequent basis.

- vessels must operate a robust permit to work system.

- The importance of using correct and concise DP checklists for both engine room and bridge.

DP Event

Published: 13 September 2016

Download: IMCA DPE 03/16

Submit a Report

The following case studies and observations have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity.

Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators and DP technical crew in appropriately determining how to safely conduct their own operations. Any queries should be directed to IMCA at [email protected]. Members and non-members alike are welcome to contact IMCA if they have experienced DP events which can be shared anonymously with the DP industry.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.