LTI: Crewman burnt in fire following release of flammable gas from hand rail

What happened?

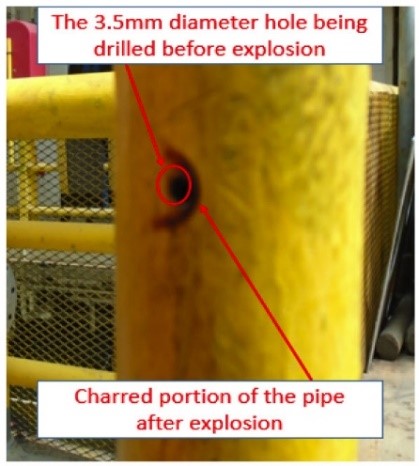

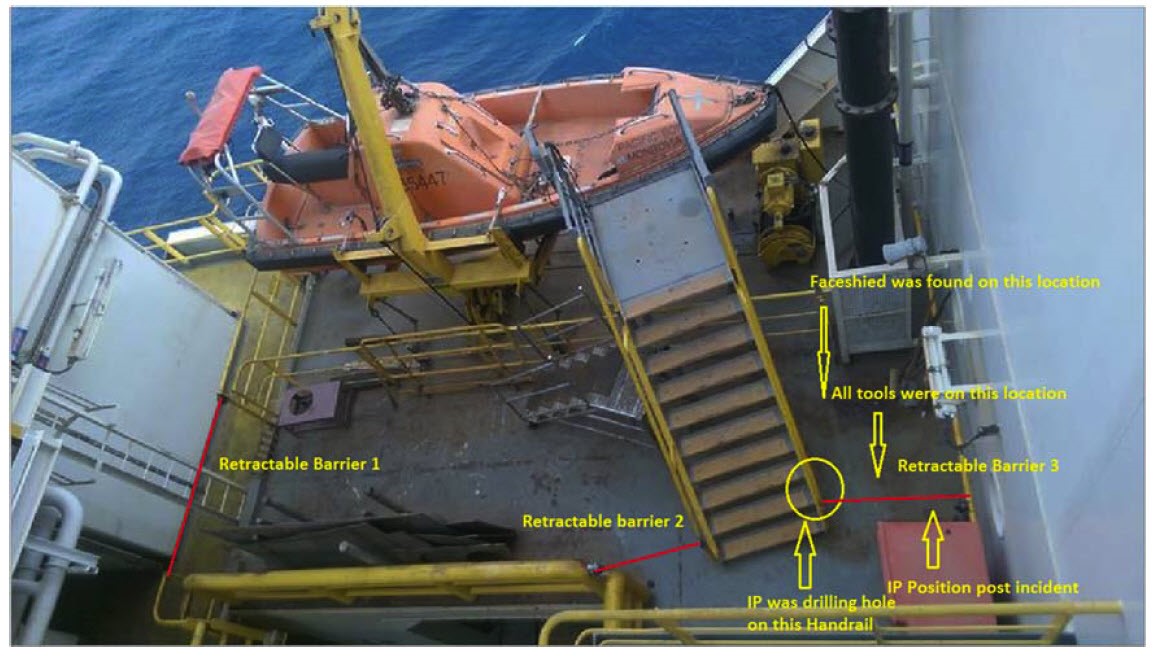

A mechanic was drilling a 3.5mm hole into the access stair handrail of a rescue craft, in order to install a safety barrier clip. When the drill bit penetrated the wall of the handrail pipe, there was a release of an unknown flammable gas that caused a fire and subsequent injury. He suffered burns which required recovery time in hospital and lost days from work.

What went wrong? What were the causes?

- The design of the handrail, using/creating hollow and enclosed structures, led to the conditions for accumulation of hazardous gas. There were no design features to allow for venting. The construction of the handrail (of low grade steel) contributed to the accumulation of a combination of hazardous gases in the hollow and enclosed structure;

- The drilling introduced a heat source for ignition of the hazardous gases when released;

- The mechanic was in the path/route of the hazardous gas release (line of fire), and was not wearing his personal protective equipment (PPE) with all fastenings secured, as was required.

The Investigation team believes that the injured person was carrying a paper copy of the risk assessment for the job in – but sticking out of – his right side front pocket at the time of the incident. It is believed that when it burned, an intensified heat spot was created which contributed to the degree of severity of the burns suffered.

What lessons were learnt?

- The injured person and his supervisor were not aware of the presence of the hazardous gas; as such the hazard/risk was not identified nor the risks reduced before starting the job;

- Hazardous gas can be accumulated over time in hollow and enclosed structures. Specific standards/procedures should be in place for work on such structures;

- The risk assessment in place for this task did not address the potential presence of hazardous gas accumulation in a hollow and enclosed structure.

What were the actions?

- Handrail design should consider features/measures to limit or avoid the potential for accumulation of gases inside hollow and enclosed structures. Examples include using angle irons for hand rails, non-metallic tubulars, weep or vent holes in tubulars, etc.;

- Establish procedures to safely tap into a hollow and enclosed structure which potentially has hazardous gas inside;

- PPE to be worn as designed, with all fastenings secured.

The reporter notes that “alerts from at least 3 known previous incidents of similar nature in the E&P industry had not been seen prior to the incident. Sharing lessons learned is important and necessary for prevention of similar incidents.”

See the Centers for Disease Control and Prevention website for an article on the explosion hazard from hydrogen gas generation inside sealed frames.

Members may also wish to review the following incidents:

- Near-miss: Release of trapped pressure after ROV dive

- LTI: Contact with refrigerant gas causing hand injury

Safety Event

Published: 27 June 2017

Download: IMCA SF 16/17

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.