Stored energy near miss: Person nearly hit by equipment caught during light daughtercraft operations

What happened

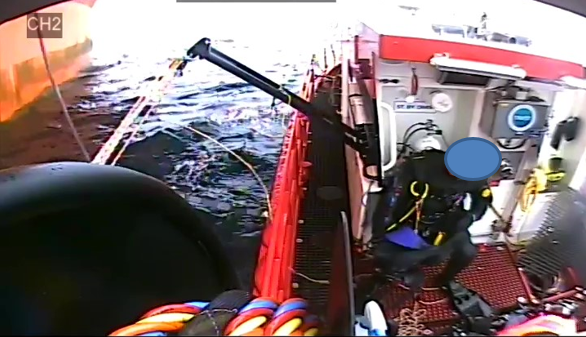

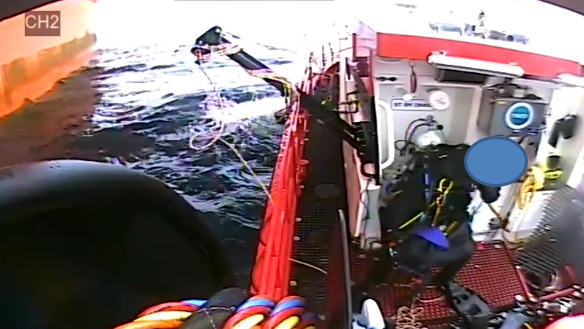

A stand-by diver on a light daughtercraft (LDC) was nearly hit by a flying block and tackle, which was thrown towards him by an unplanned release of tension during mooring operations. The incident occurred when a team of divers were carrying out a familiarisation diver rescue drill in preparation to work from an LDC alongside a floating production storage and offloading unit (FPSO). In preparing to return to the mother vessel, the LDC was disconnected from two mooring lines suspended from the FPSO. The forward FPSO mooring line caught under the T section of a removable diver rescue davit arm installed on the LDC. This created a tension on the arm which self-released, causing the arm to move very suddenly. Attached to the end of the arm was a block and tackle weighing approx. 1.5kg. This was jettisoned at head height and flung towards a bulkhead adjacent to the stand-by diver.

What went wrong?

Investigation concluded that the incident occurred as a result of the LDC drifting forward whilst being made ready for transit, with the diver rescue davit in the deployed position. The deck crew on the LDC were preoccupied in the stowage of equipment and did not notice the LDC had drifted forward to the point where the forward mooring line was midships with the LDC. When the coxswain engaged the motor to depart the worksite, the mooring line had caught under the T-section of the diver rescue davit; when the LDC turned to starboard, the davit arm forcefully recoiled to its stowage position.

What were the causes?

- The coxswain console is on the starboard side of the LDC and is fitted with a TV monitor for observing both sides of the LDC. The port monitor was not working; the cox could only see the starboard side;

- The diver rescue davit had been left in the deployed position as a diver recovery drill had just been concluded;

- The team were under the impression they were required to hurry back to the mother vessel. As a result, preparations for LDC transit were not thorough enough;

- Procedures for connecting and disconnecting mooring lines to the LDC did not specify that confirmation should be made that all lines were disconnected and the LDC was ready to transit.

Lessons learnt

- This was the first time that six of the seven divers on the LDC had been involved in the operation and even though all personnel had completed the diving contractor’s familiarisation programme, no time had been factored into the schedule for practical exercises;

- Interim project crew changes were partially staggered to facilitate continuity of personnel, but the number of personnel required to carry out marine type training exercises on the LDC for diving personnel was not defined;

- This particular vessel is a purpose built LDC and was fitted with a TV monitoring system to allow both the supervisor and coxswain to view deck operations. It was not clear to the crew what action should have been taken if any part of the system was inoperable.

Actions taken

- Revision of task plan to include the requirement to confirm all lines are released and the LDC is ready to depart prior to sail away from the worksite;

- Elimination of time limits for diver recovery drills;

- Revision of diving contractors’ LDC operating checklists;

- Procedures for disconnecting moorings revised to include a hold point to confirm the LDC is ready for transit;

- Revision of LDC coxswain’s job description with a more detailed responsibility for management of LDC marine operations and what actions to take in the event of any equipment failure;

- Revision of company LDC familiarisation procedure to include the requirement for diver rescue drills in sheltered waters as well as theoretical training when the majority of a dive team is changed out.

Members may wish to review the following incidents:

Safety Event

Published: 20 October 2017

Download: IMCA SF 26/17

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.