Hand injury when caught in machinery

What happened

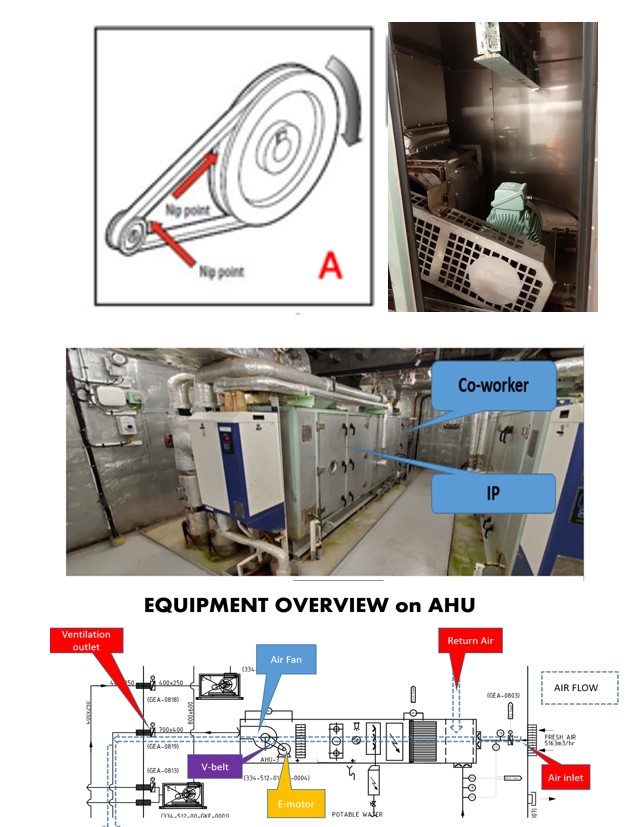

A crew member sustained injuries to his hand and arm when his hand got trapped by a moving belt. The incident occurred during routine maintenance of an Air Handling Unit (AHU) Humidifier. The AHU was confirmed as electrically isolated and the worker visually checked that the belt was completely stopped. The worker began the maintenance task as required, and happened to touch the belt with his right index and middle finger to check the tension. At this point an unexpected airflow within the ducting caused the air fan to rotate which caused the belt to move. This event lead to his glove getting caught by the belt which in turn caused his right hand and forearm to be pulled towards the machine and caught between the belt and pulley . The movement caused his right forearm to get caught between the metal guard and fixed structure around the belt.

He was transferred to hospital, where he received surgery for fractures to his right hand and arm, and returned home to make a full recovery.

What were the causes?

By opening the doors of the AHU humidifier an unexpected airflow was created by a vacuum from inside the AHU, that consequently rotated the air fan which then drew air from outside the AHU causing the belt to move. This previously unrecognized hazard was found only to happen when the ventilation outlet from the AHU to the accommodation E-deck is still in the open position. This scenario was re-enacted with several other AHU’s on board and only the 2 Top-deck AHU’s (#2 and #3) were found to have this unplanned event when the ventilation outlet was still in the open position.

Lessons learned – how to stop it happening again

- A review and update of procedures taking into account the previously unrecognized hazard, providing clear instructions;

- Expecting the unexpected – particularly with any kind of large rotating machines, and when there is a great deal of potential energy that can be unexpectedly released.

Members may wish to refer to the following events where there have been unexpected unfavourable outcomes:

- Finger injury caused by incorrectly secured console cover [which closed in an unplanned and unexpected way]

- Control module failure caused main engine sudden reduction to idle speed [“root cause was assumed to be extremely unfavourable conditions (hot and humid) in the engine room, leading to unexpected and unpredictable failures”]

Safety Event

Published: 1 February 2021

Download: IMCA SF 04/21

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.