Sustained load cracking in aluminium manufactured from aluminium alloys HE30/AA6082 and AA6351

This information note is to make members aware of IMCA Safety Flash 07/18, which is copied below.

A susceptibility to sustained load cracking (SLC) has been identified in cylinders manufactured from aluminium alloys of specific grades, manufactured between 1963 and 1995. Sustained load cracking is a metallurgical anomaly occurring in cylinders that have remained pressurised for sustained periods of time.

WorkSafe New Zealand Safety Alert

There have been two recent incidents of serious harm in the Asia-Pacific region caused by the catastrophic failure of self-contained underwater breathing apparatus (SCUBA) cylinders manufactured from aluminium alloy 6351. As a result of these incidents in August 2017 WorkSafe New Zealand issued a Safety Alert entitled “Cylinder design approvals withdrawn”.

In its Safety Alert WorkSafe New Zealand announced that it had decided to withdraw approval for SCUBA and self-contained breathing apparatus (SCBA) cylinder designs which used aluminium alloy 6351. The withdrawal came into effect from 31 October 2017.

UK Health and Safety Executive (HSE) Safety Bulletin

On 8 March 2018 the UK HSE issued Safety Bulletin ED 1-2018 entitled “Cylinders manufactured from aluminium alloys HE30/AA6082 and AA6351 and used primarily for gases for underwater breathing apparatus”.

The publication of this bulletin was prompted in part by the Asia-Pacific incidents, but also by an incident of serious harm caused by the failure of an HE30/AA6082 cylinder in England in 2017.

The UK HSE bulletin states the following:

These cylinders should only be used if they have undergone thorough visual inspection and testing with an eddy-current device by a competent inspector (see inspection and testing requirements below).

Failure to conduct such inspection and testing could result in serious harm.

Cylinders to be inspected and tested include those used for SCUBA diving, those that supply breathing air through an umbilical hose and those used to fill SCUBA cylinders.

If you are unable to determine whether a particular cylinder is made from one of these alloys, remove it from service, safely release the gas and do not use it until the alloy can be identified and proper inspection and testing can be conducted.

- Cylinders that cannot be identified from markings on the cylinder must be removed from service, condemned and rendered incapable of holding pressure.

- Cylinders that fail visual inspection or eddy-current testing must be condemned and rendered incapable of holding pressure.

IMCA Guidance to Members

In view of the information provided by the Worksafe New Zealand alert and the UK HSE bulletin, IMCA recommends that cylinders manufactured from aluminium alloys HE30/AA6082 and AA6351 are not used on member worksites.

Members are advised to take the following actions:

- Check if any cylinders are manufactured or suspected to be manufactured from aluminium alloys HE30/AA6082 or AA6351.

- Check for specific alloy-related markings or for a date of manufacture (the earliest date stamped on the cylinder) prior to 1995. If there is reason to believe that a cylinder may be made from either of these alloys, then the cylinder should be removed from service. The gas should be safely released, the cylinder rendered incapable of holding pressure, and safely disposed of.

- If it is not possible to determine the alloy and appropriate information, e.g. if the cylinder markings are missing or cannot easily be read, then the cylinder should be removed from service. The gas should be safely released, the cylinder rendered incapable of holding pressure, and safely disposed of.

Identification of Affected Cylinders

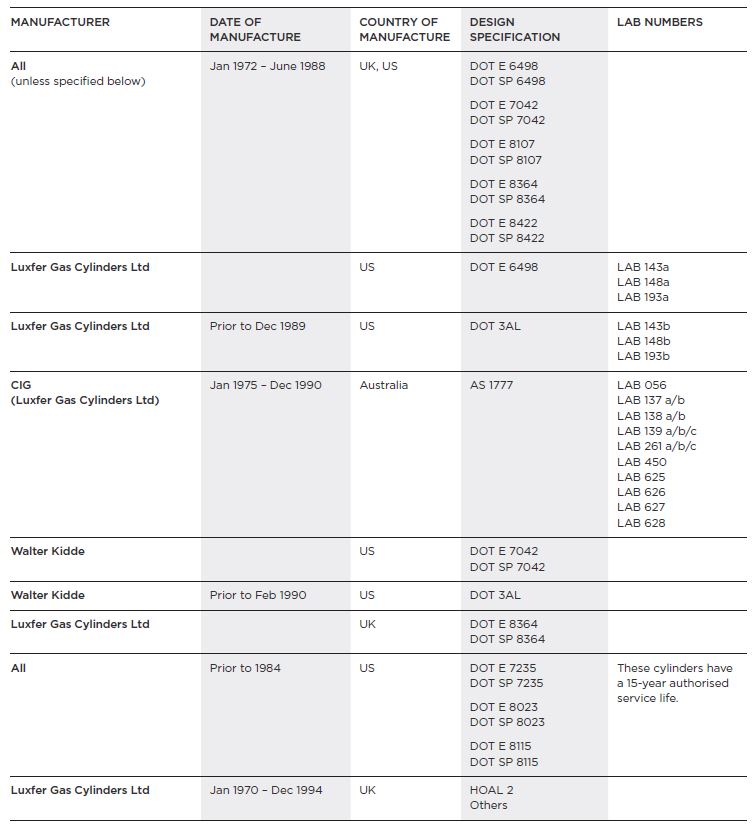

The WorkSafe New Zealand Safety Alert contains a list of cylinders affected by the withdrawal of WorkSafe cylinder design approvals. This has been reproduced overleaf as a means of assisting members to identify affected cylinders.

The UK HSE Safety Bulletin contains the following guidance on identifying cylinders manufactured from HE30/AA6082 and AA6351 aluminium alloys.

Cylinders stamped with any of the following markings are manufactured from HE30/AA6082 or AA6351:

- HE30

- HOAL 1

- HOAL 2

- HOAL 3

- HOAL 4

- BS5045/3/B

- BS5045/3/B/S

- AA6351

- P****X (as part of serial number)

- P****P (as part of serial number)

Note: On some small cylinders manufactured at Luxfer’s Aldridge, England, plant, the above markings may not be present. In that case, the alloy can be determined from the three-digit type number stamped around the base. If the three-digit number is of the form 1**, 3** or 5**, then the alloy of manufacture is AA6351.

IMCA Contact

Bryan McGlinchy

Diving Consultant

Contact

Information Note Details

Published date: 22 March 2018

Information note ID: 1405

Related Guidance

- Dive technician competence and training

- Protective guarding of gas cylinder transport containers (quads)

- Guidance on auditing of diving systems

- Code of practice for the initial and periodic examination, testing and certification of diving plant and equipment

- Diving Equipment Systems Inspection Guidance Note (DESIGN) for surface orientated (air) diving systems

- DESIGN for saturation (bell) diving systems

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.