Hangar door failure and collapse

What happened?

Whilst a vessel was working, there was a failure and collapse of the moonpool hangar doors. Deck crew were working in the area of the moonpool, when they heard a loud bang. When they turned around they could see that the hangar door had fallen down and folded in the guide rails. The door was 7.2 meters wide, 13 meters high and weighed approximately 200 kg. There were four crew members in the hangar at the time of the incident.

What went wrong? What were the causes?

The suspension points for the hangar door leaf had failed.

The causes were:

- Inadequate and weak design for holding hangar door leaf to head box;

- Increased wear and tear because there were no formal instructions or procedure for the operation of the hangar door;

- Possible additional wear and tear due to suction from the moonpool;

- Hangar doors were not part of the recommended planned maintenance system (PMS), and it was not possible to inspect the suspension points holding the door leaf.

What lessons were learned?

- Highlight the importance of knowing the operational limitations or requirements for any equipment;

- Ensure that personnel operating equipment (e.g. hangar doors) are properly familiarized with it;

- Consider further possible risk of potential dropped or falling objects, especially where inspection of condition is not possible.

What actions were taken?

- Implemented proper instructions for the operation of hangar doors and updated familiarization;

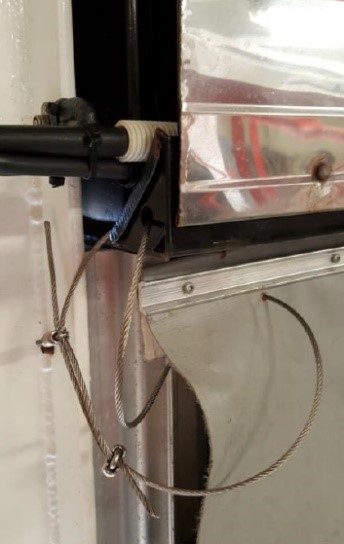

- 6mm stainless steel flat bar was installed inside an aluminium profile holding the folding door to header box in order to make the construction more rigid and solid;

- Installed safety lashings to prevent the folding door upper mount from falling to deck if overloaded.

Members may wish to refer to the following incident:

Safety Event

Published: 9 July 2018

Download: IMCA SF 14/18

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.