Ruptured acetylene hose: Fire

What happened?

A subcontractor was preparing to use an oxy-acetylene torch on the back deck of a vessel. The oxygen and acetylene cylinders were located on the quayside with the hoses rigged to the vessel. On lighting the torch, a ‘pop’ sound was heard, and a small fire was observed from a rupture of the acetylene hose just ahead of the flash-back arrestor.

What went wrong?

The actual cause of this incident could not be established. However, flash-back can occur when a flammable mixture remains in the blowpipe or hoses when the torch is lit. Ignition can travel towards the cylinder but is normally stopped by the flash-back arrestor, which prevents decomposition of the acetylene or an explosion.

What actions were taken?

Our member took the following actions:

- Regularly check the condition of oxygen and acetylene hoses and ensure they are replaced as required in any planned maintenance system (PMS) or supplier instructions;

- Keep torches in good condition to avoid turbulent gas flow and so reduce the risk of flash-back;

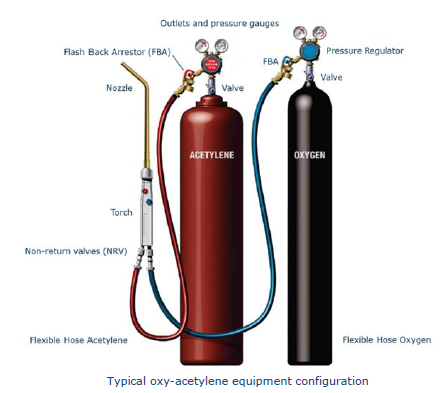

- As a minimum there should be a non-return valve at the torch end of each hose and a pressure or temperature variation activated flash-back arrestor at the cylinder end;

- Only use regulators, flash-back arrestors, hoses and blowpipes which are designed for either acetylene or oxygen and are clearly marked and manufactured to the correct standard;

- Ensure that flash-back arrestors are being replaced at least every 12-months;

- Welding gas hoses should be correctly connected, and jubilee clips should never be used;

- For cutting and purging operations the oxygen and acetylene hoses should be separately purged to remove any flammable mixtures before lighting the blowpipe;

- Monitor and confirm the subcontractor’s compliance to the above requirements.

What lessons were learned?

Our member gave the following advice to crew for what to do if a flash-back occurs and it is safe to do so:

- Immediately close the oxygen nozzle valve and then the acetylene nozzle valve (NB: this is the opposite of the normal closing down sequence);

- Close both oxygen and acetylene cylinder valves;

- If the flame cannot be put out at once, evacuate the area and raise the alarm. For onshore sites or for a vessel which is alongside alert the emergency services;

- Once the situation is secured, the equipment must be quarantined until it can be fully examined for damage and either confirmed safe for reuse or safely disposed of;

- Never attempt to move or vent a cylinder but monitor for any heat generation;

- If a hotspot is detected on the acetylene cylinder evacuate the area, raise the alarm and where appropriate, notify the emergency services, if safe to do so apply cooling water.

Members may wish to refer to:

Safety Event

Published: 28 October 2019

Download: IMCA SF 25/19

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.