Steering motor failure leads to loss of both aft thrusters – DP incident

Case narrative

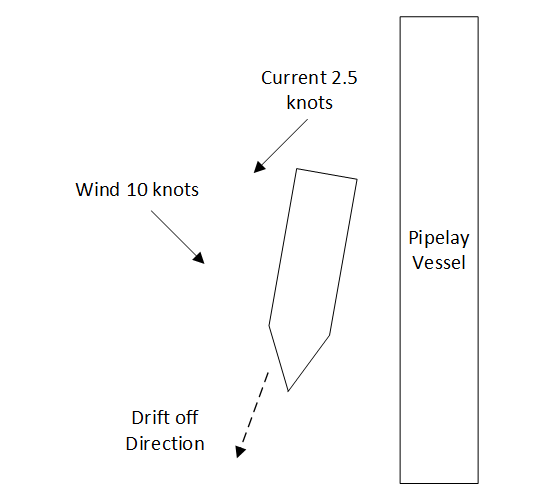

A DP2 cargo vessel was working close to a pipelaying vessel conducting cargo operations in a drift off position. The current at the time of the event was 2.5 knots which, in conjunction with 10 knots of wind, resulted in an external force of 30 tons acting on the port quarter.

The port azimuth thruster failed as a result of failure of both steering motors. One of the two starboard azimuth thruster steering motors also failed; however, the thruster remained available due to the remaining healthy steering motor. Cargo operations were immediately ceased, and attempts were made to restart the port thruster unsuccessfully. During these attempts, the starboard thruster tripped due to a ‘low hydraulic pressure’ alarm.

With no aft thrusters available, the vessel drifted for around 200m before power was regained to one of the starboard steering pumps allowing the thruster to restart. The vessel was subsequently manoeuvred outside the 500M zone for failure investigation.

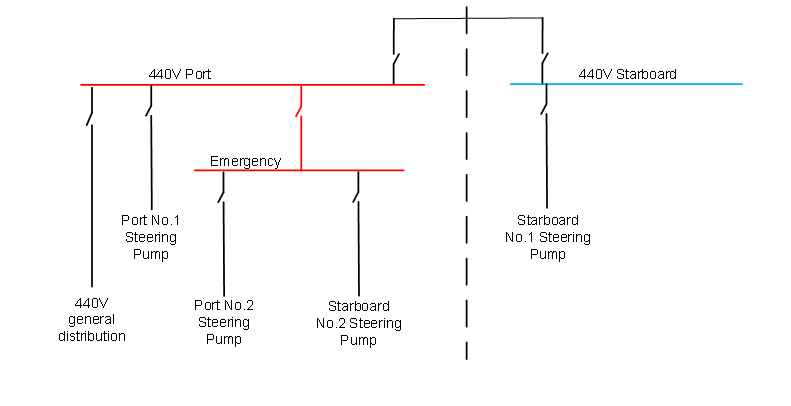

At the time of the event, the vessel was being operated on automatic DP2 mode, with 4 generators and 4 thrusters online. The main 690V, 440V and 220V switchboards were being operated with open bus tie; each side of the main switchboard powering one forward and one aft thruster as per the proven redundancy concept.

The supplies for port and starboard steering pumps were arranged in the same manner. Each pump was driven by electric motor controlled by variable speed drive (VSD). Steering pump no.1 for each thruster was supplied directly from the respective port or starboard main switchboard and steering pump no.2 for each thruster supplied from the emergency switchboard. The emergency switchboard was connected to the port main bus bar.

The investigation revealed a gradual but significant earth fault within a consumer supplied by the Port 440V general distribution panel. The Earth fault was caused by a trapped cable within a motor connection box. The cable had been trapped between the lid and body of the box during a recent maintenance inspection.

This earth fault had been detected by the sophisticated protection systems of the VSDs controlling the steering pumps on the port and emergency switchboards, but not the starboard switchboard as the bus tie was open. The VSDs tripped causing the three steering pumps to fail. Note that the VSDs are unable to differentiate whether an earth fault is upstream or downstream, therefore they will typically trip assuming that the earth fault relates to the equipment they control.

The remaining starboard steering pump tripped due to a low hydraulic pressure alarm. The cause identified in the investigation report as a faulty seal. Although there is no direct connection between this failure and the earth fault causing the other steering pumps to trip, the seal damage may have been exacerbated by the demand caused by the loss of the other starboard steering pump.

The Lessons

- The investigation report highlighted that the crew had properly set the vessel in DP2 mode and positioned the vessel in a drift off location. Despite their best efforts, they could not have positively affected the outcome of this failure.

- The earth fault, although caused by an unrelated consumer, caused the VSDs in question to trip. The investigation report highlighted that other VSDs of the same type did not trip therefore the VSD manufacturer was in the process of investigating the protection parameters of all VSDs on-board to determine any potential setting adjustments.

- The earth fault was caused by a trapped wire following equipment maintenance. The level of earth fault appeared to get progressively worse over time; however, this seemed to go unnoticed until the event occurred. The investigation report did not detail whether or not there was suitable switchboard earth fault monitoring installed. Nonetheless, this event clearly highlights the risks of inadequate earth fault monitoring and indeed procedures to be followed when such earth faults are measured/develop.

- The seal that failed on the starboard steering pump was found to be a known defective product. The investigation revealed that sister vessels had experienced the same seal failure and as such the investigation report highlighted the need to take a fleet wide approach to replacing the seals and ensuring critical spares were available on-board.

- Although there is no discussion regarding the DP system FMEA in the investigation report, the FMEA should have considered that there was the potential for cross connections and failure of port and emergency switchboards simultaneously. There should then have been FMEA proving trials confirming the outcome of such failures. This testing would have revealed that there was potential for loss of 3 out of 4 of the aft steering pumps.

Considerations of the IMCA Marine DP Committee

This case study demonstrates the challenge that exists when there is a classification rule requirement to install secondary equipment and supplies from the emergency switchboard, and the subsequent risks that the DP system design is then exposed to from a common mode/single point failure/cross connection perspective.

Such factors should be analysed within the vessel’s DP FMEA. Analysis should then be confirmed through FMEA proving trials and subsequent DP Annual Trials Programmes with any necessary mitigating measures (technically or procedurally) put in place.

DP Event

Published: 29 November 2019

Download: IMCA DPE 04/19

Submit a Report

The following case studies and observations have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity.

Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators and DP technical crew in appropriately determining how to safely conduct their own operations. Any queries should be directed to IMCA at [email protected]. Members and non-members alike are welcome to contact IMCA if they have experienced DP events which can be shared anonymously with the DP industry.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.