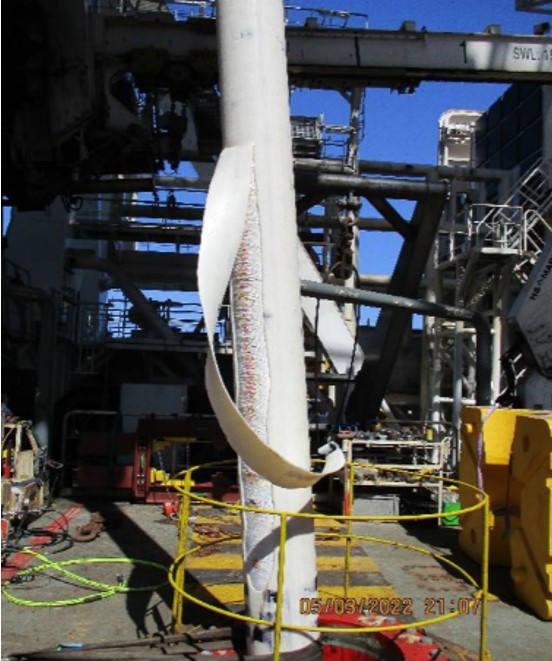

Damage to flexible riser

What happened?

During deployment of a water injection riser from a vessel, damage to the outer coating occurred when it came into contact with the sharp edge of the flare in the moonpool area. A water injection riser was being installed through a project-supplied flare in the moonpool via the vessel’s Tiltable Lay System (TLS) at an angle of 6.8°. The flare had been designed to direct and protect the riser at the exit. However, design reviews, subsequent risk assessments and inspections had failed to identify the hazard of the sharp upper lip of the flare with the potential to damage the riser.

What went wrong

- During design the sharp edge of the flare had not been identified as a hazard and therefore, was not chamfered for protection of the product;

- The project risk assessment did not identify proper controls to prevent and mitigate possible damage to the product or its coating due to seabed topography, tilted TLS etc;

- Lessons had not been learned – previous learnings from similar flexible product damage events had not been transferred to the project team prior to design.

Recommendations

- Learn the lessons! Learnings from previous or similar flexible product damage events to be reviewed and considered during the full life cycle from design to installation;

- During design reviews and risk assessments specific to flexible products, ensure sharp edges and potential hazards that can cause damage are considered and mitigated;

- Project supplied equipment to be integrated into lay systems should be reviewed by vessel team before fabrication and then again at installation.

Members may wish to refer to:

- Uncontrolled movement of a riser

- Three incidents in which something similar had happened before – in all three incidents a similar incident had happened previously, and lessons were not learned:

Safety Event

Published: 20 July 2022

Download: IMCA SF 18/22

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.