Case Study – Importance of Units

1 Overview

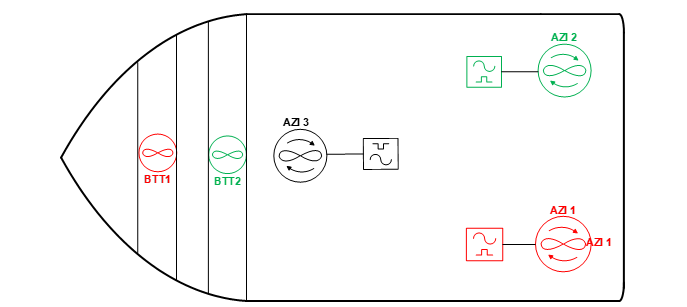

Upon completion of DP field arrival trials, the vessel began sub-sea operations. One ROV was deployed and the crane was in use subsea. The vessel set the two stern thrusters AZI1 and AZI2 to bias, in addition the bow drop-down thruster AZI3 was set to bias mode.

Biasing was set at 0.5t with a turn factor of 50%. The vessel lost position due to stern thrusters oscillating thrust against each other, ramping up to over the 50% turn factor causing them to kick into variable mode.

An all stop was called and the crane and ROV’s were recovered to deck. The stern thrusters continually circled around their azimuths, unable to meet their set points. The stern thrusters continued to increase their thrust up to 100% causing the bow thrusters to ramp up as well. The excess thrust increased the demand on the available generators on each side of the bus (open bus), starting the 2 remaining standby generators. Vessel heading was lost by 5 degrees, and the position up to 10m.

The DPO then disengaged the sway axis to allow the thrusters to settle down. Control of Sway was kept by joystick command. Once stable, the DPO put the thrusters back into biasing and reengaged the sway axis. The vessel then stabilised and kept position until the ROV and Crane were back on deck.

2 Events leading up to the incident

The vessel owner was requested by the charterer to use metres as distance units for DP Control, the DPO then changed all DP parameters from feet to metres to suit.

An on-coming DPO then changed offset values from their correct value in metres to feet believing that feet were the correct value for the DP Control System. However, the DP system was still selected to operate in metres.

As the vessel heading became less stable as environment increased the DGNSS positions were less accurate and the DP system became critically unstable.

3 What can be concluded?

- Poor management of change, logging of system settings, handovers, etc.

- Poor Communication.

4 Additional Comments

- It is unclear why the DPO did not deselect the bias mode when the thrusters began to ramp up.

- It is unclear what the environmental forces were in the lead up to the event. Bias mode is often chosen for light environmental conditions to prevent the azimuth thrusters ‘hunting’ however this mode is not generally suitable for higher environmental conditions.

- The event report did not mention the use of ASOG. An ASOG would have assisted in the decision making process whether in an increasing environmental situation or in which modes to operate in and when.

- The units of measurement can be changed for the HMI presentation within the DP controller. This is a selection available to the DPO. The DP controller accuracy and quality is not influenced by the units chosen. The variable settings for the DP controller are set during the tuning of the DP system by the OEM engineer and are not accessible for the DPO.

5 Guidance that would be relevant

The following IMCA Guidance would be relevant to this case study:

DP Event

Published: 11 August 2022

Download: IMCA DPE 02/22

Submit a Report

The following case studies and observations have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity.

Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators and DP technical crew in appropriately determining how to safely conduct their own operations. Any queries should be directed to IMCA at [email protected]. Members and non-members alike are welcome to contact IMCA if they have experienced DP events which can be shared anonymously with the DP industry.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.