Near miss: pipe dropped from pipe supports

What happened

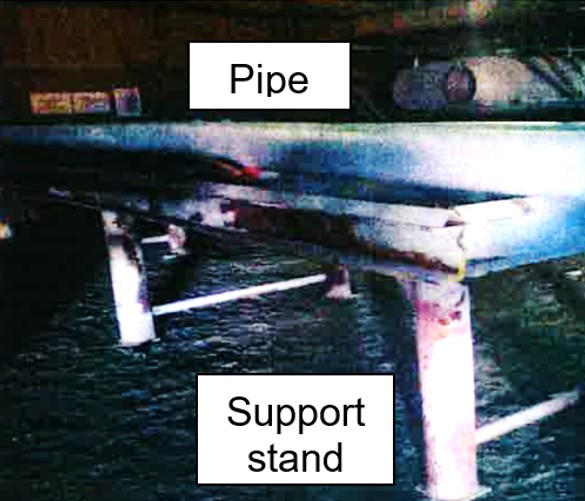

During the cleaning of a section of pipe at a third-party facility, the pipe rolled off the pipe support easels and dropped to the floor. There was no injury to personnel nor damage. The incident happened when a worker was using an angle grinder with an abrasive sanding wheel to clean the pipe. The pipe was supported by two easels at either end with only minimal wedges or restraint to prevent the pipe rolling off the supports. The worker turned the pipe to get to the underside and during this action the pipe rolled off the supports dropping to the ground.

Our member reports that this is the third incident in the last 12 months with a similar cause – inadequate supports used while working on pipes.

What went wrong the following findings were noted:

- There were inadequate supports used for working on and storing pipes;

- There was a failure in procedures and risk assessments, to address the manual handling aspects of pipes on temporary supports;

- There was a failure to learn from previous industry incidents;

- Previous inspections and audits had failed to verify controls and preventive measures;

- Human factors, risk perception and competency of personnel involved in operations.

Recommendations

- Ensure effective risk assessment of temporary pipe stand / support arrangements;

- Use rollers or other mechanical devices to turn a pipe;

- Managing third party suppliers and contractors:

- Set clear expectations on what should and should not be done;

- Have formal agreements in place on the level of oversight, mode of control and accountability;

- Schedule audits, inspections, and verifications of third party operations;

- Support third party contractors and consider regular fresh eye reviews of work tasks and equipment in use.

• Remember that you can and should STOP THE JOB if you think it is unsafe. Don’t hesitate to do so.

Members may wish to refer to

Safety Event

Published: 13 December 2022

Download: IMCA SF 28/22

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.