Cut and bruise to right hand whilst pressure testing

What happened

A technician was pressure testing hydraulic hoses in the hydraulic workshop using the water pressure test bed. He had previously tested two hoses earlier in his shift. On completion of pressure testing the third hose the technician opened the drain valve and witnessed the gauge go down to 0 bar. He then proceeded to remove the blanking flange from the opposite end of the hose he was testing. When doing so a release of pressure occurred knocking his hand onto the wall of the test kit resulting in a laceration to the palm and a bruise to the back of his right hand.

What were the causes

- The technician assumed that as the reading on the gauge had dropped to zero, it would be safe to release the fitting. But the larger volume equated to a longer drain time;

- Pressure was trapped because the connection was mistakenly slackened too quickly after opening the drain valve. This resulted in the check valve in the hose to close and trap the remaining pressure in the hose. The hoses were “Minimess” hoses;

- Though the gauge on the control panel was reading zero it would have taken a few more seconds for the pressure to dissipate from the test hose due to the larger (3.75cm) diameter;

- Pressure was released when the technician started to remove the blanking flange.

Learnings identified

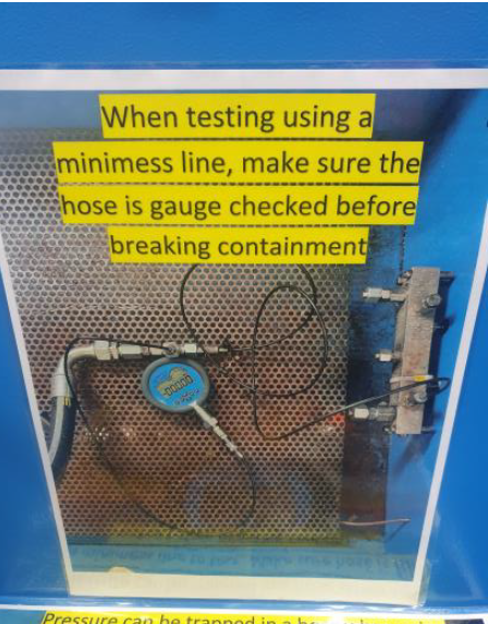

- Create a routine duty for the testing of “Minimess” hoses and update the appropriate task risk assessment;

- WAIT a moment! Allow a delay of 10 seconds from when main pressure valve is opened, and always install a second gauge on the test hose after the “Minimess” to ensure the test hose has zero pressure;

- Post better instructions on the test rig reminding users of precautions when testing hose and to ensure pressure is drained from the test hose.

Members may wish to refer to:

Safety Event

Published: 4 April 2023

Download: IMCA SF 09/23

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.