Case Study – Hybrid Failure

1 Overview of the Event

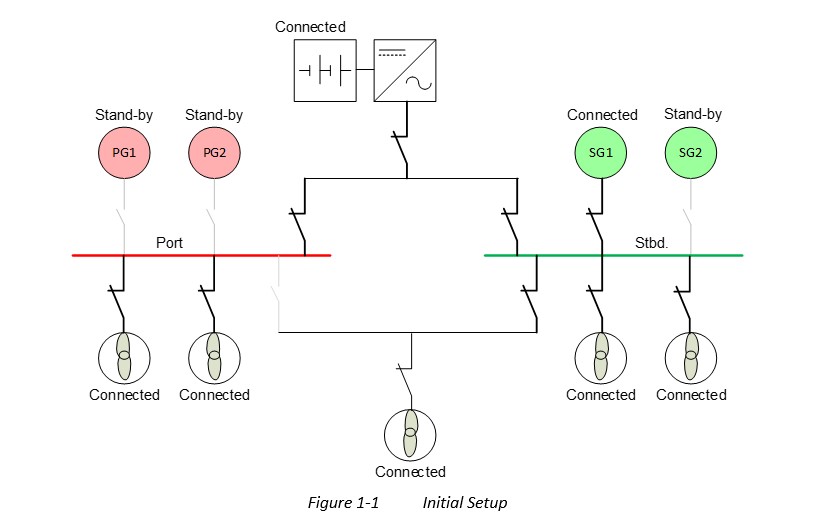

A PSV was conducting DP operations within a 500m Zone. The vessel had an energy storage system (ESS) fitted and was configured closed bus with a single generator connected as per below:

Three out of the five thrusters were powered from the starboard switchboard with a single generator connected. The port switchboard provided power to two of the five thrusters, with no generators connected. The two electrical systems were linked with the ESS connected to that link.

A malfunction in the battery converter system caused the battery incomer circuit breakers to trip, resulting in the separation of the switchboard, the loss of power to the port switchboard and the subsequent failure of two thrusters. The generators PG1, PG2 & SG2 automatically started and connected to restore power. There was no positional loss.

2 What can be concluded?

- The vessel was operating within its Worst Case Failure Design Intent (WCFDI) environmental constraints.

- The protection system operated as designed.

3 How can lessons learned from this event be applied to prevent future DP incidents?

- The vessel was conducting cargo operations beside a fixed asset.

- The vessel was operated as designed for DP redundancy but shows that failures can happen in the ESS ‘static’ power supply. i.e. failures are not just reserved for spinning (dynamic) machines.

- The significance of a proper FMEA, annual DP trials, and CAM-compliant setup. Understand your vessel for both DPOs and Engineers.

- Do not wait until the Consequence Analysis alarm has activated. Stay within the weather window of the present configuration, as partial blackouts can happen at any time.

4 Guidance that would be relevant

- The following IMCA Guidance would be relevant to this case study:

- IMCA M220 – Guidance on operational planning

- IMCA M250 – Introduction to hybrid battery systems for DP vessels

- IMCA M103 – Guidelines for the design and operation of dynamically positioned vessels

- IMCA M166 – Guidance on failure modes and effects analysis (FMEA)

- IMCA M190 – Guidance for developing and conducting DP annual trials programmes.

DP Event

Published: 29 June 2023

Download: IMCA DPE 02/23

Submit a Report

The following case studies and observations have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity.

Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators and DP technical crew in appropriately determining how to safely conduct their own operations. Any queries should be directed to IMCA at [email protected]. Members and non-members alike are welcome to contact IMCA if they have experienced DP events which can be shared anonymously with the DP industry.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.