MSF – two recent dropped object incidents

The Marine Safety Forum has published safety alerts on two recent dropped object incidents, both of which have learning value for IMCA members.

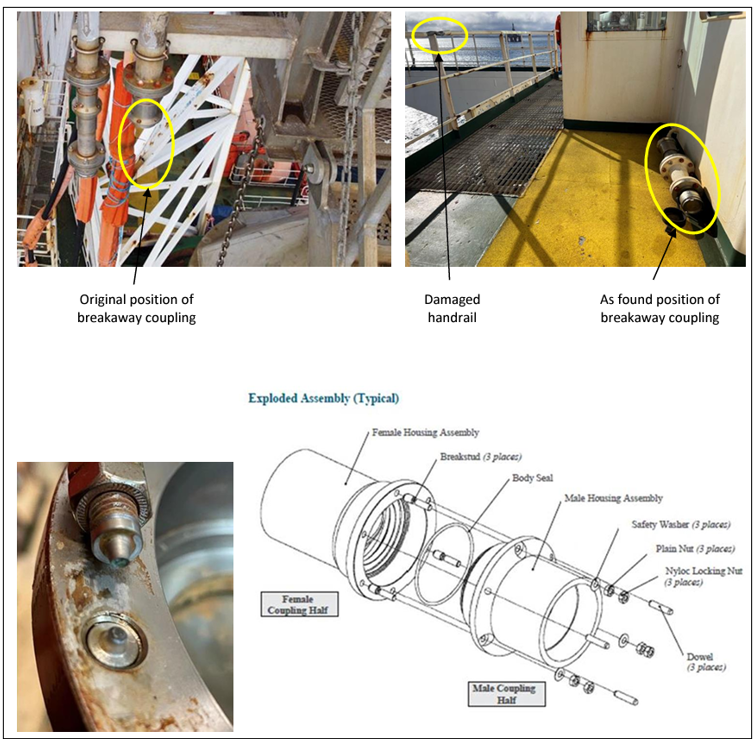

Incident 1: What happened

A breakaway coupling became a dropped object. It fell unnoticed to deck on a semi-submersible accommodation vessel. Later investigation identified where the breakaway coupling had fallen from. Another coupling was found with early signs of failure, with one of the breakaway studs found loose and able to be moved around freely.

What went wrong

The MSF notes that planned maintenance of the couplings was not aligned with OEM guidelines – it was found that the breakaway studs had been in place for longer than OEM recommendations. Also, the vessel was in lay-up and there was no reason for the couplings to be in place during layup. The couplings should have been removed at end of contract to remove any risk of a dropped object.

Actions

- Amend planned maintenance system to reflect OEM requirements and recommendations;

- Amend procedures to ensure hoses and couplings are not left in situ at height, when this is not required;

- Review potential use of drop net / secondary restraint.

See Breakaway Coupling becomes a Dropped Object for further details.

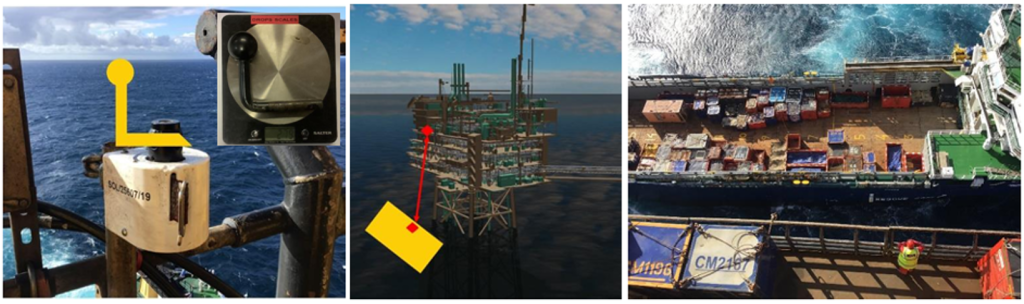

Incident 2: What happened

A barrier tape mechanism handle weighing 278g fell 45m from an offshore platform onto the deck of a supply vessel. During routine supply vessel operations, a deck crew person on an offshore platform was establishing barriers for safe lifting of cargo onto the platform’s weather deck. On extraction of the fixed barrier tape the handle was seen to eject from the mechanism and fall, eventually landing 45m below onto the deck of a supply vessel. Whilst nobody on the supply vessel was on the deck at the time, this had the potential to have been a fatality.

What went wrong

This type of barrier tape was only used by the offshore platform deck crew and was all fixed to the outboard handrails near laydown areas. The handle was fastened with a grub screw to a round shaft with no keyway or secondary retaining mechanism. The design is such that as the tape spools out the handle spins; this provided the lateral force to allow the handle to eject out over the handrail and down onto the supply vessel deck. A review of other new and older mechanisms onboard found similar loose moving handles but none that would readily fall out.

Actions

- Check if similar barrier tape mechanisms are used and check integrity of handle fixtures;

- Consider relocation away from handrails to remove the potential for rotating mechanisms to fail and fall to levels below, the sea or supply vessels.

Members may wish to refer to

Safety Event

Published: 15 August 2023

Download: IMCA SF 20/23

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.