LTI: person slipped climbing out of tank

What happened

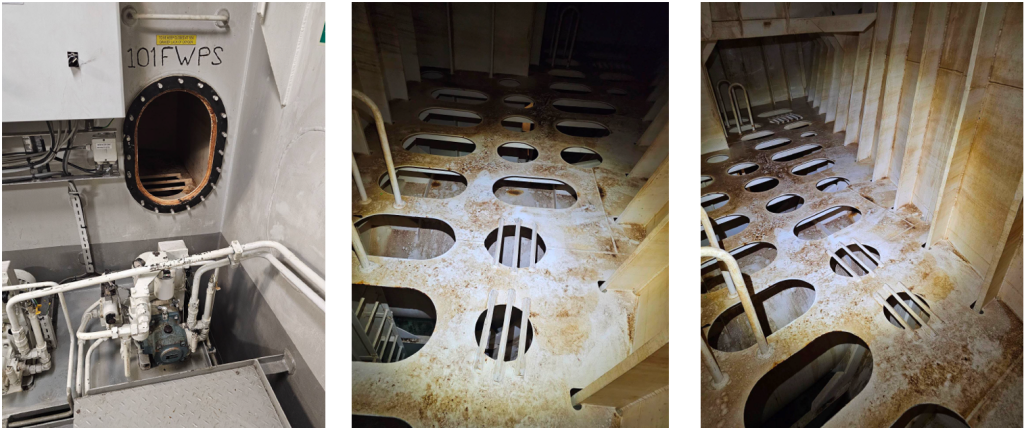

A crew person was injured getting out of a fresh water tank on a vessel. The incident occurred during cleaning of the tank. The injured person was in the process of exiting the tank for a rest break. He was on the same level as the entry/exit hatch for the tank. As he was heading to the tank exit hatch, he slipped and during the fall he reached out with his right hand to help cushion his fall. He has been carrying a torch in one hand, nothing in the other.

He was attended to in the ships hospital for treatment and then it was necessary for him to be taken ashore for further medical treatment. He was unable to return to the vessel due to the nature of the injury – a closed fracture of the right forearm.

What went right

The two crew persons involved in the operation followed all appropriate safety controls for entry into the confined space of the tank – Permit to Work, toolbox talk, rescue plan etc. They were trained and competent in confined space entry and were wearing full and correct PPE for the task.

What went wrong

Our member’s investigation noted that the root cause was a slippery surface in the tank due to water pooling from the cleaning operation. The inner surface of the tank was a painted smooth surface, i.e. becoming slippery when wet.

- This kind of tank entry was considered routine work with an elevated risk to it due to the design and confines of the tanks;

- The risk was high due to the use of water to clean the tanks which in turn creates a slippery surface where there is potential for slipping over and consequent potential injury;

Lessons learned

- Review schedule for Fresh Water Tank inspections to see if they are being completed too frequently and exposing crew to risk;

- Review the coating requirements for tank to see if it is feasible to apply non-slip coating to the tanks to prevent slips.

Members may wish to refer to

Safety Event

Published: 27 March 2024

Download: IMCA SF 07/24

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.