MSF: Serious hand injury – high pressure air

Hand and finger injuries

Members continue to report hand and finger injuries. In last year’s safety statistics, 42% of LTIs reported by IMCA members involved injuries caused when workers got into the Line of Fire. What do we need to do to stop workers putting their hands and fingers in dangerous places? We all want to get the job done – but that one quick pause, whilst we stop to think, could make ALL the difference. Think:

- Is there a better way to do this?

- Could I use a tool instead?

- Should there be a guard? Should I have gloves on?

- Is this still too hot to touch? Is it live or is it still spinning?

- Think carefully before putting your hands where you can’t see them.

What happened

The Marine Safety Forum (MSF) has published Safety Alert 24-05 relating to a finger injury caused by a release of high pressure air. The incident occurred during a vessel fire drill; the fire team were being assisted with putting on Breathing Apparatus (BA) sets. The assisting crewmember inadvertently opened the BA set valve resulting in a release of high pressure air. As a result, the crew members’ finger was impregnated by the high pressure air. The finger that was impregnated showed immediate signs of swelling and the medical support teams advised medevac by helicopter. The injured crew member required surgical treatment, to confirm the extent of the injury and ensure there was no debris injected, and to reduce the risk of infection and tissue damage.

What was the cause

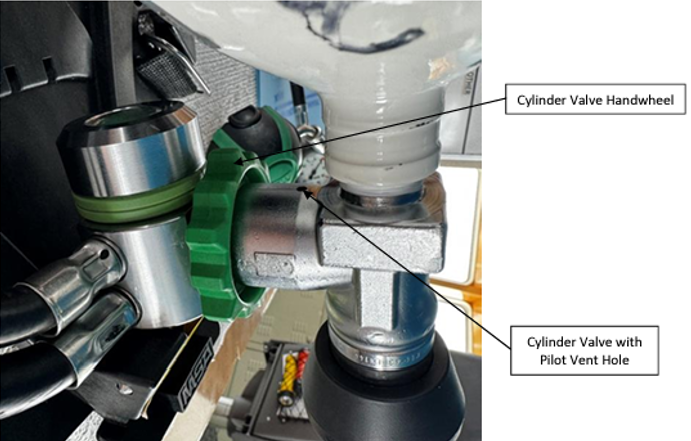

Investigation found that there was a momentary high-pressure air release from the Pilot Vent Hole – a safety feature in 300 bar rated cylinder valves. The injured crewmember must have inadvertently placed his finger over the Pilot Vent Hole at the moment there was a momentary release of pressure.

Recommendations (MSF)

- When replacing a BA bottle on a BA set always ensure that the Cylinder Valve Handwheel connection is tightened as per manufacturer’s instructions;

- After changing the BA bottle, pressurize the system and listen for any leaks. Test for bubbles caused by leaks using soapy water at the connection points. Tighten connections, if necessary, but close the main valve first;

- Ensure the pressure gauge reflects the correct pressure;

- Conduct a breathing check by inhaling through the mask to ensure air is flowing correctly;

- Verify the low-pressure alarm is functioning properly by momentarily turning off the air supply. When conducting planned maintenance checks the above should also be adhered to and checked;

- When putting on BA, manufacturer’s instructions should be followed, and if any leaks are observed the main cylinder valve must be closed prior to tightening.

Members may wish to refer to:

Safety Event

Published: 14 August 2024

Download: IMCA SF 16/24

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.