Diver exposed to unplanned release of production gas

What happened

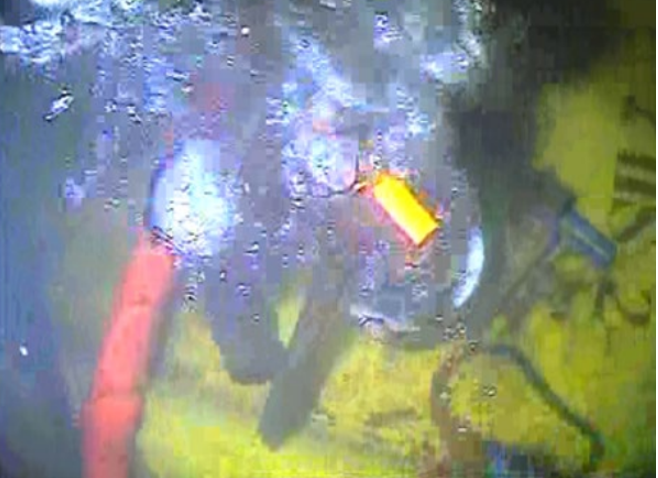

During saturation diving activities at 65m water depth, from a Diving Support Vessel (DSV), a diver was exposed to a sudden and unplanned release of hydrocarbon gas under pressure (estimated pressure >150bar). The pressure release resulted in ejection of a stuck blind stab and the diver being pushed backwards by the force of the gas. The diver was unharmed. Our member considered the incident to be a very high potential near miss.

Nearing the end of the bell run, saturation divers were working on a subsea skid when they identified incorrect tagging. Work was stopped and the divers were then instructed by the Diving Supervisor to proceed with a dummy stab removal at the same location, using hand tools (T-Bar and hammer). During initial hammering of the dummy stab, a discharge of gas bubbles was observed coming from the receptacle, followed by a larger one. At this time, both divers were instructed to stop working for ten minutes to allow for the gas to discharge. Diver 1 was instructed to return to the bell and Diver 2 was subsequently instructed to restart tapping the blind stab with the hammer. Suddenly the dummy stab ejected and trapped production gas was released. Diver 2 was positioned just outside the line of fire, but he was pushed backwards by the force of the gas release, though he remained on the top of the skid.

What went wrong

- Unlike the isolation in place for previous work, the isolation of this skid could not be demonstrated because of the configuration of the pipework and because there was no way to vent the void behind the blind stab;

- Dummy stab removal with diver and hand tools was a deviation from procedure. There was no time out taken to discuss the change in task or initiate a Management of Change procedure;

- The Dive Supervisor had previously used divers to remove blind stabs, which created a normalisation of this way of working;

- The task Specific Risk Assessment was not adequately reviewed at the Toolbox Talk;

- ROV tooling developed for blind stab removal was available and ought to have been used as per the task specific Risk Assessment but was not used;

- Specific task plans were not developed for diver dummy stab removal;

- Several people could have intervened and stopped the job but did not. Only one person – the Pre-Commissioning Engineer had a concern and highlighted the non-compliance with procedures, but did not exercise stop work authority;

- The divers continued with dummy stab removal despite the gas bubble release without challenging the ‘as-found’ condition.

Actions to consider

- The incident has similarities to a previous incident that occurred during diving operations in the North Sea (see reference below). It is important to verify that lessons are learned from previous incidents and that preventative and critical controls from high potential incidents are in place;

- Recognise how we really do things – The “Stop Work Authority” needs to be reinforced across all worksites and operations;

- Be curious, keep questioning all aspects of what may go wrong. Dedicate time to go through all potential risks to consider and implement adequate mitigation controls.

- Remind and empower our personnel to stop, ask the question(s), assess then act.

- Avoid becoming complacent by continually asking oneself “what if …?”

- Remind each other that we have procedures and processes which are there to help us.

- Review procedures and task plans to ensure that there are critical “hold points” included detailing the use of the ROV tools.

Members may wish to refer to:

Safety Event

Published: 11 November 2024

Download: IMCA SF 22/24

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.