Failure of a high pressure gas charging hose

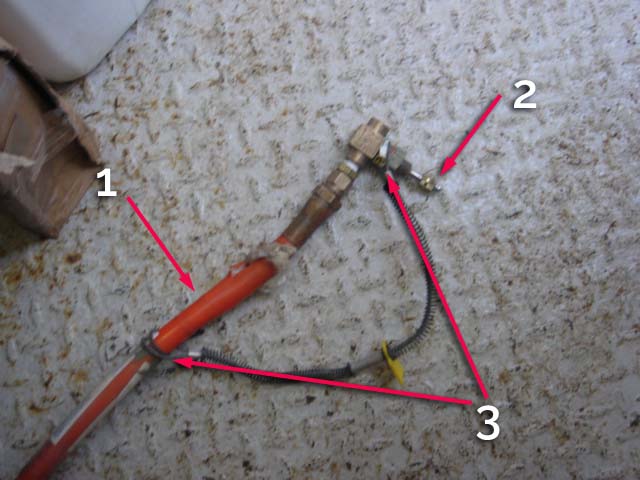

A member has reported the failure of a high pressure (HP) gas charging hose during routine gas decanting to top up the gas banks of a mobile surface supplied diving system which had been installed into a small craft used for remote diving operations.

During the gas bank decanting, an HP gas charging hose ruptured and its recoil force caused shear failure of an isolation valve fitting which was serving as an anchor for the HP hose whip check.

The resulting failure of the valve fitting connection caused a restrained flailing of the hose and valve fitting which became entangled on the structure of the small craft.

All gas banks were immediately isolated, which prevented any personnel injury or further equipment damage.

After investigation by the company involved, the following points were highlighted:

- The whip check was anchored on a pressurised valve;

- There was a failure to recognise the force of recoil and effect on the whip check anchor point;

- The safe positioning of personnel performing the operation was inadequate.

Members are urged to consider the following:

- A review of whip check anchoring methods on all HP hoses;

- An inspection of all hoses for any indication of defect;

- The use of dedicated anchor connection points for whip checks;

- An alternative design of whip check that ensures the whip is held at the very end of its length i.e. Chinese finger style;

- A review of the service life for high pressure flexible hoses looking at the original date of whip manufacture and how many pressurisation cycles the whip has had.

Safety Event

Published: 20 December 2007

Download: IMCA SF 10/07

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.