Lifting operations: wire hoist rope failure

What happened?

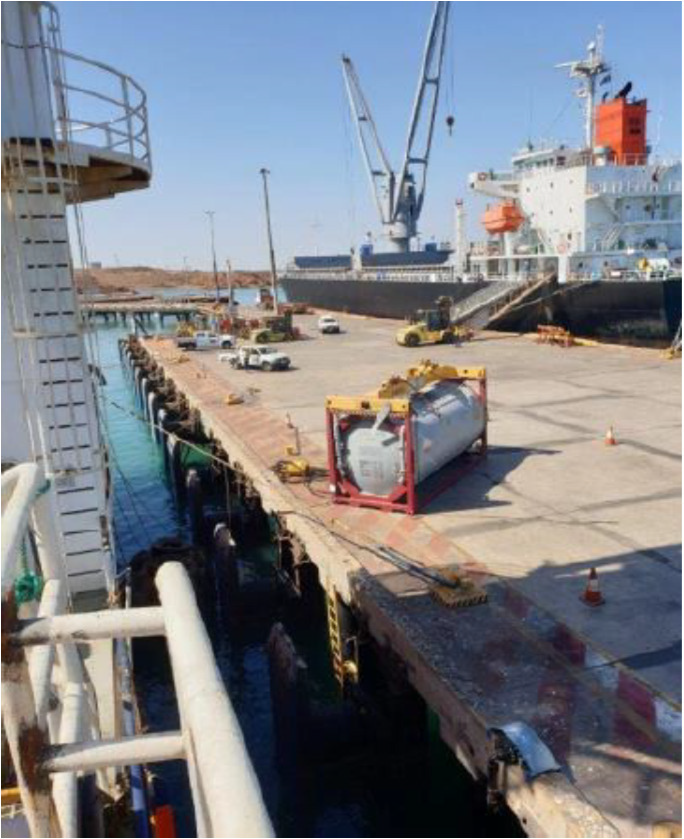

When conducting a standard lifting operation of a 24.5te storage vessel and lifting frame (approximately 36% of the crane 70te maximum rated capacity) the wire hoist rope (WHR) failed causing the load, main block and length of wire to drop approximately 3m to the wharf. No personnel were injured.

The maintenance, inspection, and testing regime applied to the WHR was consistent with general industry practice, guidelines, and company requirements and included third-party examination and certification. However, localised internal corrosion of the wire hoist rope (WHR) went undetected.

The metallurgical examination conducted on the wire hoist rope after the incident concluded that the wire hoist rope failed by a ductile overload mechanism following corrosion damage during service, particularly of the core wires. The lack of protective zinc galvanised coating on the wire hoist rope was a significant contributor to the eventual failure.

What lessons were learned?

- Reliance on ‘industry practice and guidelines’ alone when maintaining, testing and inspecting wire hoist ropes may not be sufficient. Frequency of use, intended loads, environmental conditions, time in service, and criticality of the wire hoist rope should be specifically considered;

- Implement crane wire maintenance regimes for specific individual wire rope types using original equipment manufacturer input coupled together with a competent person’s assessment of the risks, giving due regard for the operating environment and intended use of the crane/wire rope;

- Establish criteria to determine when and how magnetic wire rope (MRT) testing should be applied (frequency, triggers, length of wire).

Members may wish to refer to:

- High potential dropped object – satellite dome fell from mast

- Near-miss: corrosion-related failure of bolts used to secure lifeboat winches

- Near-miss: Corrosion caused crane boom failure during heavy lifting

- Guidance on wire rope integrity management for vessels in the offshore industry (IMCA LR 001, IMCA HSSE 022, IMA M 194)

Safety Event

Published: 28 April 2020

Download: IMCA SF 14/20

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.