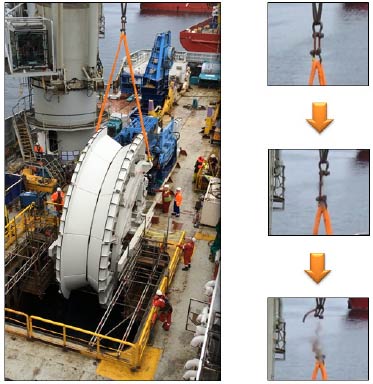

Master link failure during testing of overboarding chute

A member has reported an incident in which a master link failed during articulation of an overboarding chute. As one of the final stages of mobilisation of a jumper deployment spread to a project vessel, an overboarding chute (circa 25Te) was being function tested on completion of securing to deck grillage. The function test involved operating the chute articulation mechanism by connecting to the crane main line to lift and move (traverse) the chute from its upper resting position, past top dead centre then lowering into its lower (deployment) position where it rests on stoppers and is secured via swing bolts. As the chute went through top dead centre a 38.3Te master link failed in the rigging assembly resulting in the chute making an uncontrolled movement forward, into its deployment position. Based on crane data the load applied to the chute hinge mechanism (between chute and grillage) at the time of failure was circa 80Te; more than 50Te greater than the weight of the chute assembly. It should be noted that the crane data indicates the load at failure exceeded the Safe Working Load (SWL) (38.3Te) but did not exceed the Minimum Breaking Load (MBL) of 153.2Te.

The chute sustained damage in several areas to the extent that it and the deployment spread had to be demobilised from the vessel. No-one was injured but the potential existed for a person to be struck by the failed master link as it fell to deck.

Our member’s investigation noted the following:

- Whilst the immediate causes of the incident contributed to the failure of the master link, the root cause was attributed to a failure to develop and apply an effective safe system of work;

- The deployment spread mobilisation procedure did not include the function test;

- No lift plan was in place for task despite being identified as an existing control measure in the hazard identification and risk assessment (HIRA);

- The absence of details on expected loads, lift plan, and required crane movements was not challenged;

- Operations review, HIRA and procedure approval process did not recognise the risk of lifting the chute while attached to the deck (over pull). There was also no indication that this was considered at site either;

- The requirement to closely monitor the load was not recognised;

- Analysis of the failed master link identified defects that could have caused failure below MBL. The process of establishing the cause of the defects was ongoing.

Our member concluded that although rigging failures such as the above were relatively few in comparison to the frequency of lifting operations in our industry, there was no cause for complacency in our approach to working around suspended loads. In all cases the complexity of lifting activities must be understood in order to ensure the task is suitably planned and risk assessed. Where there is any apparen’t lack of information or concerns then this must be openly challenged and resolved.

The following actions were taken:

- Reviewed all master links onboard; quarantined any William Hackett 38.3Te master link with batch number H678/1-8;

- Management/Supervisory personnel to discuss alert with their teams and reinforce expectation that anyone can request further or challenge information that may compromise the safety of the task; . Recognise the potential risks associated with moving loads that are attached to the deck (or similar) as part of reviews, and ensure an appropriate level of detail in procedures, lift plans and risk assessments accordingly.

Members may wish to review the following similar incidents (key words: master, link):

Safety Event

Published: 25 November 2014

Download: IMCA SF 18/14

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.