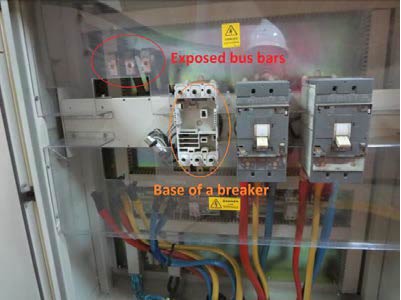

Near-miss: Inadequate insulation of 690V bus bars

A member has reported a near miss incident in which 690V bus bars were found with inadequate insulation. The 690V switchboard had been isolated for a survey, and the panels were opened for inspection. It was observed that not only had the breakers been removed, but the bases had also been removed leaving exposed bus bars. It was also noted that the wire terminations were not fully insulated. The bus bars would be live when the switchboard is in its normal condition, and they have a degree of flexibility, so it is feasible that as they move with vessel vibration they could arc, causing significant damage and injury to personnel if they were present in the area.

After investigation, our member noted the following:

- Nearly three years previously, two further incidents had occurred in which there were significant breaker failures on the vessel 690V switchboard which had resulted in serious injury to personnel. Short term remediation work had been carried out at that time, and a survey for long term rectification works was being carried out prior to a maintenance period;

- During this survey it was noted that there were blanks on the switchboard panel where breakers had been removed. The missing breakers supply power to a tensioner that is currently not installed. The unused tensioner breakers had been removed to be used in other areas as the vessel had insufficient spares onboard to replace all the breakers impacted by the breaker failure. They were relocated some time ago with the vessel technical management being aware of this;

- Subsequent to the initial failure and prior to the most recent survey this switchboard had undergone a full health care check by a third party which also failed to identify these discrepancies;

- There was no check made to ensure that the third party contractor’s work was carried out in a satisfactory manner;

- Spare parts were not effectively managed onboard, with parts removed as necessity at the time not being replaced;

- A management of change process was not used when the breaker and base were initially removed.

Our member concluded that:

- Work standards in insulating the terminations and leaving the bus bars exposed were unacceptable;

- Management of spare parts stock was inadequate and should be improved;

- Management of change and technical oversight needed to be improved;

- Continuity of handovers and outstanding priority works needed to be improved, especially as the personnel involved with the original incident were no longer serving on the vessel; . Third party contractors require robust supervision and verification of completed work.

Members may wish to refer to the following similar incidents (key words: insulation, breaker):

Safety Event

Published: 25 November 2014

Download: IMCA SF 18/14

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.