Stored pressure release – hydraulic oil

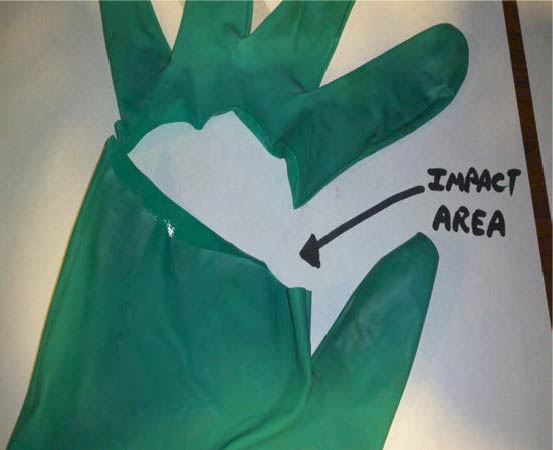

A member has reported an incident in which there was an unexpected high pressure oil discharge causing injury to someone’s left hand. The incident occurred during the reconfiguration of a trenching ROV. A crewman was disconnecting hydraulic pipe fittings to the chain tensioning cylinder on the mid digger section when there was a high pressure release of oil from a pipe fitting, which hit his left hand and sprayed on to his face causing a skin irritation.

The on-board medic assessed the injured person and raised concerns that chemical injection to the left hand was a possibility; the injured person was medevaced by helicopter to hospital for further assessment.

Our member’s investigation noted the following:

- Hydraulic pressure was trapped in the annulus side of the digger chain tensioning cylinder and owing to the hydraulic circuit configuration it was not possible to relieve this pressure without opening a pipe fitting;

- The pressure gauge for the digger chain was piped to the full bore side of the cylinder to measure the pressure exerted on the digger chain; it was possible to have no pressure in the full bore side but pressure may still remain in the annulus side, creating a situation where the annulus side could be pressurised with no indication.

The following actions were taken:

- Installed adaptor plates and drain fittings to cylinder as a means to detect and relieve pressure;

- Revised Safe System of Work with detailed information for checking for and relieving stored pressure in circuit;

- Started review on all jet trenchers and WROV to rule out the possibility of a repeat incident on another vehicle.

Members may wish to refer to the following similar incidents (key words: stored, pressure, release, hydraulic):

Safety Event

Published: 20 March 2015

Download: IMCA SF 04/15

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.