Near-miss: Hot work in no-weld zone

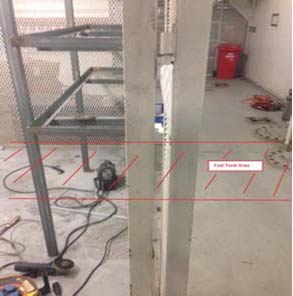

A member has reported an incident in which crew were found conducting welding operations in an area of a vessel where hot work was forbidden. The incident occurred when arrangements were being made for the installation of steel shelves in a storage cage on the upper tween deck. This area ‘upper tween deck’ is below the main deck, amidships.

A permit to work was raised for this operation and was signed by the rigging supervisor as Area Authority. The welder set up the required equipment at the worksite and was in the initial stages of the task when the Chief Engineer walked by on a ‘routine’ inspection and stopped the job. The Chief Engineer explained to the welder that he was about to weld onto a fuel tank which is located on the other side of the deck, and called an all stop.

Our member summarises a series of failures which brought about this event:

- Inadequate task plan;

- Inadequate communication of task plan;

- Lack of awareness/perception of risk;

- Inadequate attention to detail;

- Unclear/conflicting lines of responsibility;

- Insufficient warning signage;

- Following usual task;

- Poor housekeeping.

The following actions were taken:

- Reviewed this incident and communicated it to all appropriate personnel;

- Identified all no weld areas on vessels and ensured they were suitably marked/highlighted and ‘No Welding’ signage was clear from all directions;

- Ensured that vessel GA (General Arrangement drawings) were used to show location of open permits and to assist in de-conflicting permits and hot work, had all the no weld zones/areas clearly marked to assist in the approval of Hot Work permits and to prevent approval being given for hot work on ‘no weld areas’;

- Ensure that persons responsible for issuing Permits to Work were suitably trained and fully understand their roles and responsibilities;

- Ensure that those who were ‘Area Authorities’ fully understand the hazards and restrictions associated with those areas.

Members may wish to refer to the following similar incidents (key words: hot work):

Safety Event

Published: 2 June 2015

Download: IMCA SF 08/15

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.