Lifting bridle snagged – Failure to “stop the job”

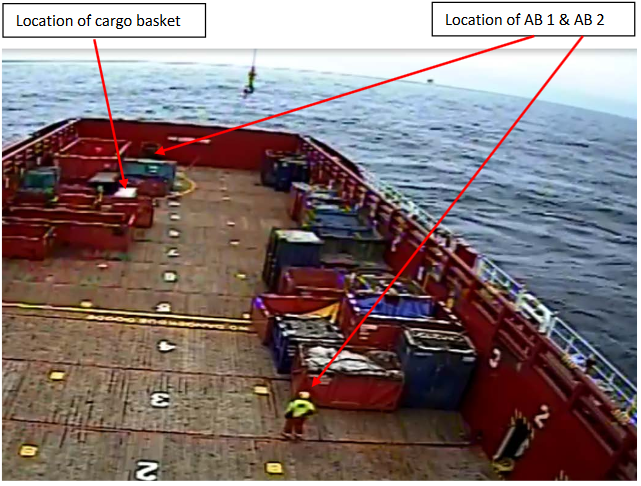

The MSF has published the following safety alert regarding lifting during cargo operations. A Platform Supply Vessel (PSV) was working alongside an offshore installation carrying out cargo operations, which included the discharge of a small cargo basket. After unhooking the previous back loaded cargo carrying unit (CCU), crewmen ‘walked the crane’ approximately 15 metres and hooked on a cargo basket – they then left the area and the crane began to take the strain. As the slack was being taken up, the lifting bridle caught under the lid of the basket. Fortunately, the crane driver noticed the lifting bridle snagging and lowered the load. Both the crewmen had walked away from the basket in different directions neither observing the basket being lifted, and so neither were aware that the lifting bridle had snagged, nor could they see each other to highlight the problem.

After a short time both crewmen made their way back to the basket and cleared the lifting bridles. They then stood clear in a safe haven nearby while the crane took up the slack but once again the lifting bridle caught on the lid, this time buckling the lid exposing the cargo inside.

The MSF made the following points:

- All involved (both on the vessel & on the installation) were reported as experienced in PSV operations;

- The crewmen on board the vessel routinely carried radios to maintain contact with the bridge and crane. All were reported as fully operational although they did not routinely talk to the crane driver during every lift;

- As the incident progressed there was minimal communication between the crane operator and the crewmen regarding what problems were being encountered and how they would proceed;

- The full operation and difficulties encountered were witnessed by at least three persons, none of whom ‘stopped the job’.

Please see Safety Alert MSF 16-15 at marinesafetyforum.org/images/msf-safety-alert-16.15.pdf

Safety Event

Published: 1 September 2016

Download: IMCA SF 22/16

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.