Corrosion damage: Failed fire hydrant

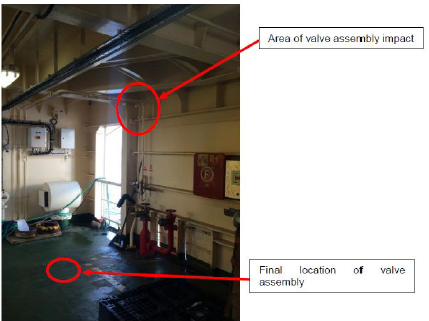

A member has reported an incident in which a fire hydrant valve failed under pressure. The incident occurred during testing of the helideck firefighting system. A hydrant valve assembly on the starboard side of the main deck failed under pressure. The 2kg valve assembly struck the deck head approximately 2 metres above, chipping paint on impact, and then fell to the deck below. No-one was injured. Whilst no-one was in the immediate area, the impact was heard by several people. The force associated with the hydrant valve assembly failure had the potential to cause a significant injury or fatality.

Our member’s investigation revealed the following:

- There was an unexpected failure of the hydrant valve assembly studs. These studs were of type 303 Stainless Steel;

- Expert analysis reveals that type 303 Stainless Steel is particularly susceptible to stress corrosion cracking (SCC) in a high ambient temperature (tropical environment);

- The failure of the studs may have been accelerated by the presence of water surge, or water hammer, in the fire-fighting water system when activating the helideck firewater system;

- Metallurgic analysis examined both “failed” and “non-failed” studs were provided by the vessel. The report stated that the cause of failure was chloride induced SCC, which is a common failure mode for austenitic stainless steels, including types 303, 304, and 316;

- SCC failures commonly occur in tropical environments at ambient conditions for SS 303 and 304 grades, particularly for items under tensile stress and where the item has been cold worked. The report stated that all type 303 studs, regardless of exposure internally to raw seawater or externally to seawater spray would have eventually experienced complete fracture through SCC;

- Equipment on vessels operating in tropical environments, exposed to relatively high environmental temperatures, will be exposed to increased risk of SCC. Austenitic stainless steels (grades 303 and 304 in particular) will fail from SCC in relatively short periods of time;

- A contributing factor to the incident was the incorrect operation of the fire-fighting system inducing water surges or hammer into the fire main;

- The root cause of this incident was the incorrect material specification of the studs for the environment and application.

Our member took the following actions:

- Careful consideration given to the increased likelihood of SCC in stainless steel for vessels operating extensively in tropical or high temperature environments, particularly for vessels designed and built in temperate climates;

- All affected studs on fire hydrants to be replaced.

Members may wish to refer to the following incidents (search word: corrosion, tropical):

- Lifting rigging on ‘Frog’ personnel transfer capsule (immediate cause: slings corroded in tropical environment)

- Lost time injury (LTI): Thumb laceration (immediate cause: aerosol can exploded following corrosion in tropical environment

- Near-miss: corrosion-related failure of bolts used to secure lifeboat winches

Safety Event

Published: 20 December 2016

Download: IMCA SF 35/16

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.