Poor maintenance and subsequent failure of welding equipment

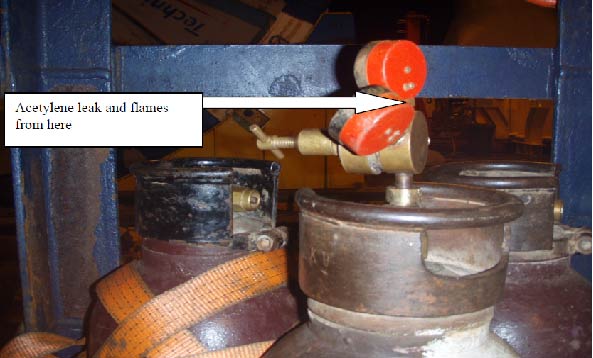

During a recent mobilisation on a member’s vessel, sub-contractors were burning and welding sea fastenings on the main deck. Following a report that flames were coming from the contractors’ acetylene tank regulator situated inside the holding gas quad, a small fire was extinguished at the regulator, which was then cooled and removed for inspection (see Figure 1). On examination it was found that thread tape was being used in all the connections on the contractors’ equipment.

Further incidents with welding equipment on the same vessel were:

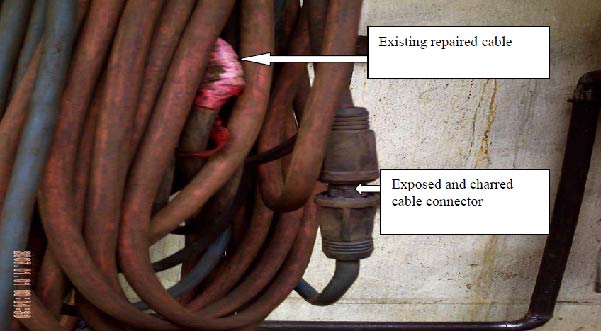

- A ship welding cable was found to be smouldering at a connection point;

- A midway cable connector was found arcing and smoking during deck welding operations;

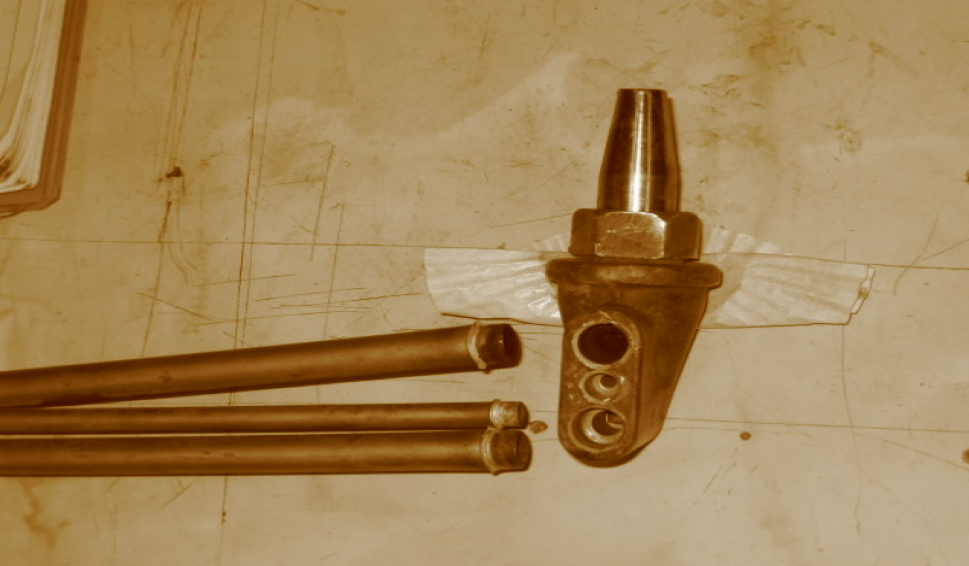

- A nozzle head was found detached from an oxy-acetylene torch.

The company would like to highlight the potential hazards of lack of control and maintenance of ship’s and sub-contractors’ welding equipment, as there have been a number of incidents involving welding equipment in a poor state of repair and being used whilst unfit for purpose onboard recently.

Members are also referred to the following incident report issued by the Marine Safety Forum regarding a further welding incident.

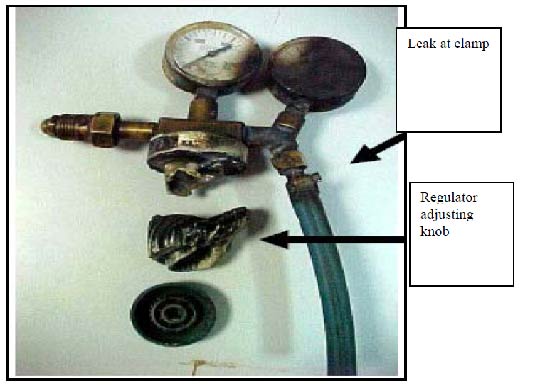

It highlights an incident involving a welder who was adjusting the pressure on an oxygen regulator. The welder had oil on his hand and there was an oxygen leak from the hose clamp. As a result the welder’s hand was badly burnt. Oxygen under pressure and hydrocarbons (oil and grease) can react violently, resulting in explosions, fire and injury to personnel and damage to property. Never allow oil or grease or any organic matter to come into contact with oxygen under pressure.

A member has provided the accompanying checklist for welding equipment which may be useful to members.

Safety Event

Published: 19 June 2009

Download: IMCA SF 09/09

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.