Case study – Switching to manual mode caused loss of position

Case narrative

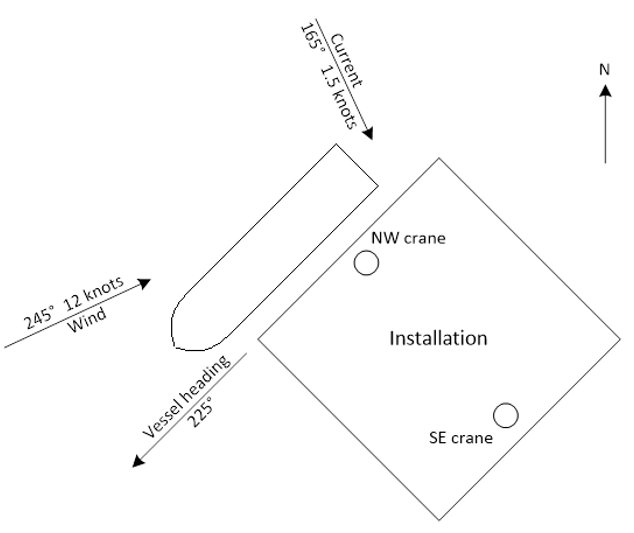

A DP2 platform supply vessel was set up on auto DP engaged in cargo operations inside the 500m zone of a fixed platform. The DP design concept of the vessel was such that there were two redundant groups and the vessel was set up with power generation and thruster supplies equally split across each redundant group with main bus ties open. Weather conditions were acceptable based on the capability of the vessel and the vessel was undertaking cargo offload on the north west side of the platform on a “blow on” position due to unavailability of the south east side platform crane.

The port aft azimuth developed a failure that led to it tripping out of DP control and its main circuit breaker opened. As the vessel was being operated within its environmental envelope and the thruster failure did not exceed the designed worst case failure, the vessel maintained position.

However, as redundancy had been compromised cargo operations were immediately suspended and the instruction was given to leave the 500m zone for thruster investigation. The DPO, in consultation with the master, decided to deselect auto DP control mode and selected manual control mode, at which point the vessel became unable to maintain its position and light contact was made with the platform before vessel control was regained. The decision was made to return to port for investigation.

Investigation highlighted that when auto DP is deselected, all thruster setpoint references move to zero for the deselected surge, sway and/or yaw axis therefore when the DPO selected the vessel to manual control all thrusters effectively stopped producing force leading to the loss of position.

The standard operating procedure for the DP system was dictated by the vessel’s DP operations manual and the vessel was set up for DP operations accordingly. The vessel had two redundant groups and the redundancy concept was such that the groups were operated separately. The vessel did not experience a failure worse than its designed worst case failure and it maintained position post thruster failure.

Lessons learned

- The decision to switch out of auto DP control in order to manoeuvre the vessel out of the 500m zone resulted in the vessel’s position loss and contact with the platform. This decision was incorrect and the DPO had a lack of knowledge regarding how the system should perform. Had DP control been maintained, the vessel could have been manoeuvred away from the platform without harm.

- The DP operations manual did not explicitly state what actions should be taken in the event of a major DP system component failure nor did it explain the consequences on station keeping during DP control mode changes. Guidance: IMCA M 220 – Guidance on operational activity planning.

Considerations of the IMCA Marine DP Committee

This case study demonstrates the importance of good understanding of the DP system and its redundancy concept such that in the event of a failure, sound judgement can be taken. The vessel in question was a platform supply vessel and by nature spends a much higher percentage of time in transit/port than in field in auto DP mode. In this type of scenario, it is vital that the DP crew are exposed to annual DP trials and regular DP exercises and drills so that experience and confidence in the system is gained during normal and failure condition. Familiarisation and training of change of thruster control mode should be a regular part of on board training. Guidance: IMCA M 117 – The training and experience of key DP personnel.

DP Event

Published: 31 August 2018

Download: IMCA DPE 03/18

Submit a Report

The following case studies and observations have been compiled from information received by IMCA. All vessel, client, and operational data has been removed from the narrative to ensure anonymity.

Case studies are not intended as guidance on the safe conduct of operations, but rather to assist vessel managers, DP operators and DP technical crew in appropriately determining how to safely conduct their own operations. Any queries should be directed to IMCA at [email protected]. Members and non-members alike are welcome to contact IMCA if they have experienced DP events which can be shared anonymously with the DP industry.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.