Dropped object from crane

What happened?

A composite block forming the end stop topping of a crane fell 20m from the crane to deck. The incident occurred after a Suez Canal transit, when it had been necessary to use the crane to lift a small boat into and out of the water. After clearing the canal, the crane had to be secured for sea. While slewing to the right, the composite block (end stop topping) fell from the top of the crane (a height of 20 m). A number of crew members were within 4m of where it landed. No-one was injured.

What went wrong? What were the causes?

Investigation revealed that the composite block was only glued instead of drilled and fastened to the crane. Rust came in between the steel plate of the crane and the composite block, which loosened it and caused it to fall off.

The root causes identified were:

- Material failure;

- Inadequate design;

- Inadequate maintenance.

An inspection was made of the aft crane, where a similar gap was observed between the steel plate and the composite block.

What actions were taken?

Our member required the following fleet-wide actions:

- Check your own cranes for loose or potentially loose objects and for rust and corrosion and consider engineered solutions to any potential problems identified;

- Consider the area immediately around the crane to be a potential dropped object zone;

- Conduct a fresh dropped object survey on the vessel.

Our member contacted the crane supplier for advice and subsequently published an internal maintenance bulletin on this topic.

IMCA notes: this incident illustrates the need to continue to pay careful attention to crane maintenance and to the clear risk of parts falling from the crane itself, in addition to managing the risk of objects falling from the load.

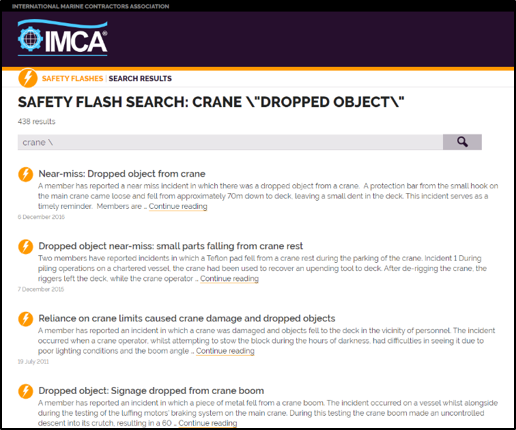

Safety Flashes can be searched effectively; rather than draw members attention to just three or four recent incidents involved parts falling off cranes, please browse our safety flash search to see a wider list of incidents involving dropped objects from cranes.

Safety Event

Published: 13 February 2020

Download: IMCA SF 05/20

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.