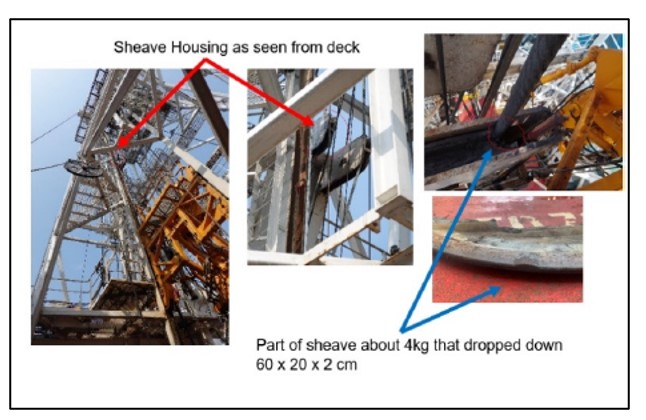

Dropped Object from Derrick

What happened?

While running in drill pipe on a drilling vessel, part of a guide sheave failed and fell approximately 15m to the drill floor. A ‘Red Zone’ was in place to restrict access to the drill floor during hazardous activities. Nobody was injured.

What were the causes? What went wrong?

The sheave had seized and failed due to a combination of the following:

- Design – lack of inspection hole in the sheave;

- A small fleet angle resulting in lateral forces on one side of the sheave;

- Installation – incorrect thickness spacer fitted by a contractor during refurbishment and a lack of a protective coating (paint);

- Quality control – inadequate inspection & testing of the installation / contractor’s work;

- Maintenance and inspection – failure to spot equipment defects and inadequacy of secondary retention.

Lessons learned

- Planned preventative maintenance systems should take account of all equipment including ancillary equipment, irrespective of whether or not the equipment was original or retrofitted;

- Robust supervision and quality control of contactors is essential to ensure that the technical specifications, installation process, functional testing and documentation requirements are complied with;

- A dropped object ‘Red Zone’ is intended to keep unauthorised personnel out of the potentially hazardous area and should be continually assessed for effectiveness.

Actions

- Amended vessel preventative maintenance system to include more detailed requirements for the inspection of ancillary equipment (e.g. sheaves, floodlights and other potential dropped object hazards) including the details of any applicable standards;

- Implemented Work Report templates to be prepared and submitted by contractors describing completed refurbishment / maintenance works;

- Revised designated ‘Red Zones’ to include “Safe Standing Zones” with overhead protective shielding.

Safety Event

Published: 4 September 2020

Download: IMCA SF 26/20

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.