Failure of bulk loading bag

Single trip tote bags are commonly used in the onshore construction industry for delivering quantities of building materials such as sand. Because of the convenience, they have been adopted in subsea construction operations for delivering a quantity of sand bags, for example, to the seabed. While one of our members’ vessels was mobilising, such a bulk loading bag failed causing the sand-bags which it was carrying, to drop onto the quayside. Nobody was hurt but the near miss incident highlighted that the practice of slinging these bags and the quantity of material which they are carrying, needed to be better controlled.

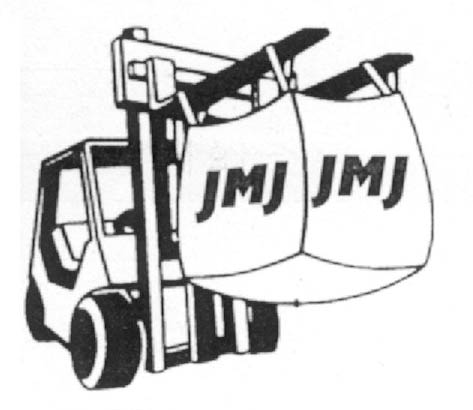

The bags are designed to be carried by a fork lift truck using the forks themselves to hold two sides of the bag as in the sketch below. Whilst this is not feasible for the member vessel’s operations, the preferred solution is that the bag should be supported from a rigid cross frame or similar such that each corner is slung vertically. Alternatively, some bag suppliers may allow the bag to be slung by a four leg sling but the length of the sling must be sufficiently long to minimise the effect of the corners moving towards each other. (Sling leg lengths in excess of 3 metres, have been stated by one supplier).

The member involved issued the following instructions to its vessels, in particular where such bags are being supplied by projects, customers or third parties:

- A suitable designed and certified lifting arrangement should also be supplied, so that the load can be applied equally at each corner of the bulk handling bag;

- The Safe Working Load (SWL) of the bag should be clearly identified and personnel instructed as to how much material this equates to (for example number of sandbags) as very often a 1te load will not even register on the larger cranes’ indicators;

- The quantity of material loaded should take into account the dynamic loading caused by high accelerations of cranes working at sea and it should be noted that wet sand is very much heavier than dry material.

Safety Event

Published: 1 March 2001

Download: IMCA SF 03/01

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.