Fall from Height Leading to Injury

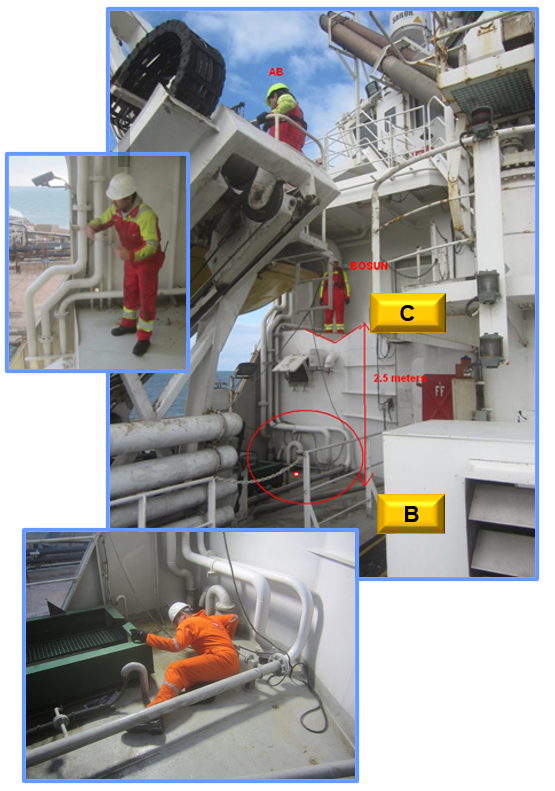

During work to change a wire on an FRC davit, a crewman lost his footing, slipped and fell 2.5m to deck below. At the end of the operation, the bosun proceeded to a place where he could monitor the stowage of the FRC. The area of deck near to where the FRC bow was stowed was uneven and sloped to allow for FRC stowage. He slipped and fell to the deck below. Due to the specific design of the vessel, there was no barrier or guard to prevent a fall when the FRC was not in the stowed position.

The bosun sustained damage to his ankle which was placed in a cast. He missed landing on several obstructions which had the potential to cause life-changing injuries had he landed on them. This incident was considered high potential by our member.

What went wrong?

- A job safety analysis (JSA) and permit to work (PTW) was performed for the job, but the hazard of falling was not identified in either;

- The incident happened during parking of FRC in what would be the clean-up phase for the wire-change job;

- The incident was not an isolated consequence uniquely generated from changing the wire on the davit but would be recurring for each launch/retrieval of FRC;

- Work on wire changing may have exposed the bosun’s safety shoes to oily residues that potentially contributed to slipping while in hazardous area on C-deck;

- The area on C-deck was not clearly marked as hazardous or no-go and the area where bosun was standing is not used during retrieval stage;

- The design of the area and the way the FRC was positioned when stowed meant the area could not be fenced off. The stowed FRC fully closes off the dangerous area, effectively mitigating the risk of falling from height.

What were the causes?

Contributing causes identified were that there was no non-slip coating, and an uneven surface, in a hazardous area. This had not been identified.

What lessons were learned?

- Improve on attention to detail – our member noted the 4C Continuous Safety Awareness methodology:

- Consider: What can happen during the task and what are the risks?

- Communicate: Talk to your team and supervisors and ensure that everyone involved remains fully aware of the risks and continues to consider all mitigating measures.

- Control: Ensure that all measures necessary to eliminate or mitigate the risks are implemented and remain in place.

- Complete: Finish the task safely;

- Importance of safety rounds/hazard hunts/inspections in different circumstances and by different people – ‘cold eyes’;

- Standardized or frequently repeated tasks are not risk free;

- The clean-up phase of a task maybe where crew are more prone to hazardous behavior;

- Develop a broader understanding of what ‘working at height’ is or could be, when considering whether or not fall arrestor gear should be employed. [IMCA notes: this is mandated in some countries.]

What actions were taken?

- Improved signage requiring fall protection equipment at certain locations;

- Review and amends to JSA for FRC launch/retrieval;

- Dedicated check on all vessels during the next hazard hunt for ‘latent’ or ‘less visible’ hazards such as:

- similar unguarded areas such as when a davit or crane is swung outboard;

- ineffective spill containment;

- Have ‘cold eyes’ perform the next hazard hunt – get someone not familiar with the space, e.g. deck crew in engine spaces or engine crew in deck areas;

Members may wish to refer to:

Safety Event

Published: 22 May 2020

Download: IMCA SF 16/20

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.