Fire in engine room on platform supply vessel

A member has reported an incident in which there was a fire in the engine room on a platform supply vessel. The vessel was on its way to port from an oil platform, when it was decided on board to run a full power test on the propulsion system which included running all five diesel generators. This is a normal ‘routine’ conducted on board approximately every month according to the vessel’s planned maintenance system.

Subsequently the fire alarm was sounded on the bridge. The bridge called the engine control room. The chief engineer was in the engine control room where he already had started to prepare for the full power test. When the bridge called, he had already detected a fire located at diesel generator number 5 and confirmed this to the bridge. At the same moment he manually released the ‘flexi fog’ fire extinguishing system above the generator and started to shut down the propulsion engines. In the meantime the crew attended their muster stations and prepared themselves according to the vessel’s Emergency Plan.

After a short time the fire appeared to be extinguished by the ‘flexi fog’ fire extinguishing system. The Master decided to send down members of the crew wearing breathing apparatus (BA) sets. Initially this was not possible owing to smoke and fumes, but once the smoke and fumes had cleared they were able to enter. When they arrived at the fire area they discovered small flames above the generator which were rapidly extinguished using a fire hose.

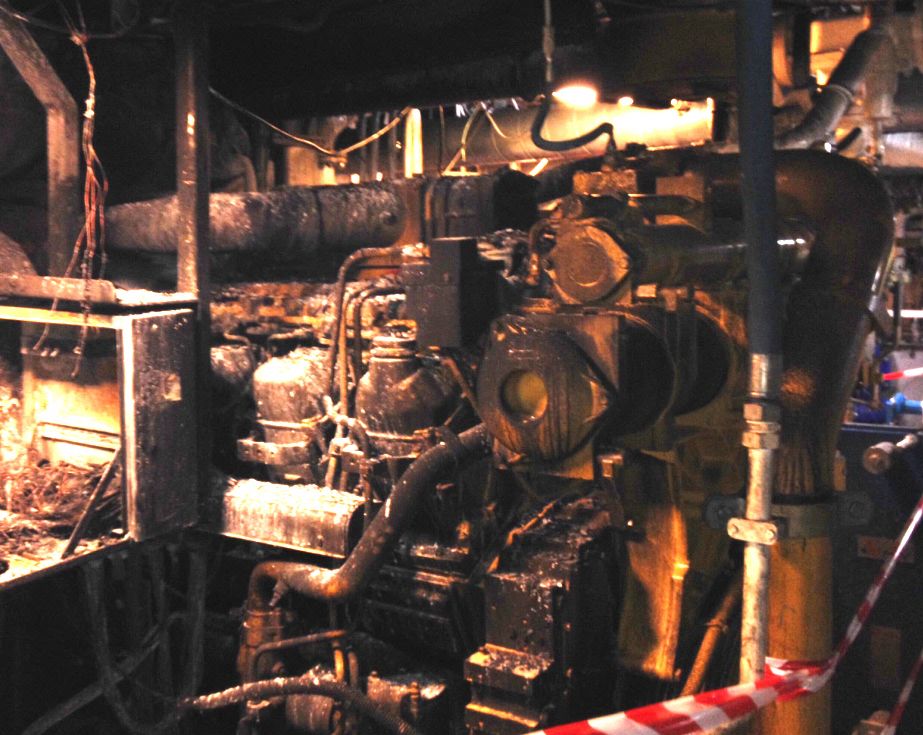

Whilst there were no injuries, there was significant damage caused by the fire. A lot of power and signalling cabling was destroyed, resulting in the vessel losing propulsion and manoeuvring ability. A tug boat was ordered and the vessel was towed to a shipyard for repairs. This resulted in six weeks off hire for the vessel.

Our member’s investigation revealed the following:

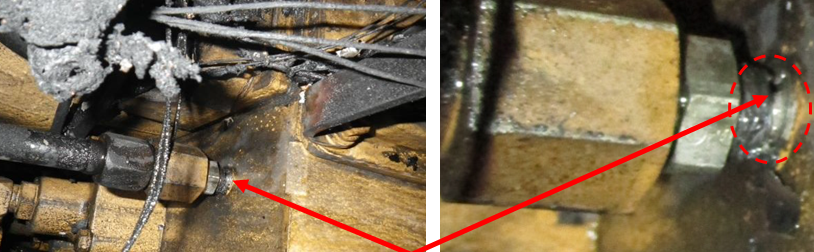

- The direct cause of the fire was discovered to be a broken lubrication oil pipe fitting leading from the generator’s engine block to a lubricating oil cyclone filter. This had resulted into an oil mist spraying out from the broken pipe. This oil mist was ignited by a source on the diesel generator or near by the generator;

- The root causes of the fire were determined to be:

- Design weakness -The piping arrangement of the lubrication system had a weakness on a pipe nipple which resulted in to an oil leakage

- Location of the smoke/fire detectors – When two of the fire detectors were activated the ‘flexi fog’ should automatically be released. It was considered that this did not occur because the fire was not detected by one of detectors above the generator -due to a poor location.

Our member took the following corrective actions:

- The oil cyclone filter and associated piping was removed and the lubrication oil pipe connection on the engine block permanently blanked off. This was done after the manufacturer of the engine was consulted about the necessity of the lubrication oil cyclone filter;

- The location and direction of the existing fire detectors was adjusted;

- Additional fire detectors were installed in the engine room to ensure enhanced fire monitoring and detection.

Engine room fires form a recurring theme in IMCA safety flashes. Typically the root causes of such fires are failures in house-keeping or planned maintenance, or failure to recognise fire hazards and address risks. members may wish to refer to the following similar incidents (key words: engine, room, fire):

Safety Event

Published: 30 June 2014

Download: IMCA SF 10/14

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.