Improper slinging of cargo

We have been passed the following, regarding an incident which resulted in cargo loss.

While making a lift from a boat to the platform, the operator picked up a cargo basket and proceeded to swing away from the boat. While swinging the basket, the cargo suddenly shifted causing the O-ring on the latch side of the hook to pull through the latch. When the O-ring pulled through the latch, the two part sling came unhooked from the stinger and the basket dropped on one side resulting in dropping some of the cargo into the water.

There were no injuries, but some of the cargo was lost.

The company concerned has identified the following errors:

- The cargo basket slings were too short to be utilised with a single point hookup causing an unstable load and one ring to pull through the hook;

- The minimum recommended sling angle (60 degrees) between the sling and the load was not maintained. Actual angle was about 35 degrees;

- The riggers on the boat failed to stop the job and used a poor rigging technique (single line stinger hook);

- The crane operator failed to observe the rigging techniques prior to starting the lift.

The company concerned has initiated the following corrective actions:

- Utilisation of two-part slings when lifting similar cargo baskets;

- Maintenance by crane operators and riggers of a minimum angle of 60 degrees between the sling and the load;

- Reinforcement by supervisors of the necessity of stopping the job when proper rigging is not being used;

- Supervisors are to review the original safety flash with all crane operators and riggers during a safety meeting.

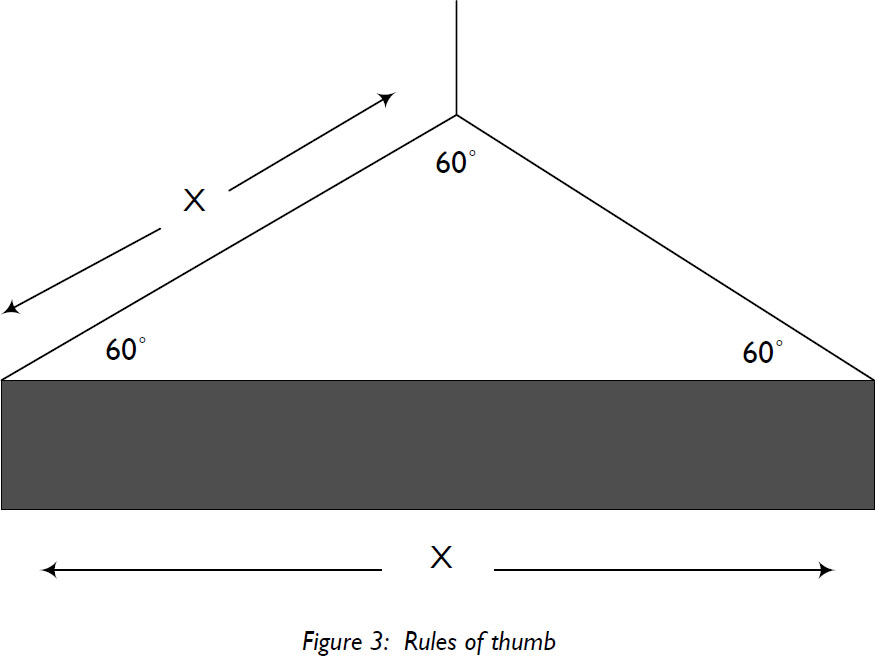

The company has set out the following ‘rules of thumb’ for rigging:

- Use the same number of pickup slings as the number of o-rings on the load rigging;

- Each sling leg should be at least equal distance between the load pickup points (forming an equilateral triangle) regardless of whether using a single stinger or two legged hook-up. This will always give the preferred 60 degree sling angle.

Safety Event

Published: 1 November 2001

Download: IMCA SF 13/01

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.