Incident involving a McKissick N419 snatch block

IMCA recently received notification of an incident involving a particular type of snatch block, which could be knocked apart if the bolt and hairpin were removed and the block left open in an unloaded condition. In the incident described to IMCA, a component part had been knocked free and dropped from a height.

Correspondence between IMCA and the manufacturer showed that blocks produced prior to 1991 allowed removal of the head fitting, albeit after removal of the hairpin and bolt and rotation of the head fitting to an extreme position. Blocks produced since 1991 have a feature that requires a deliberate component removal to allow the head fitting to be removed when the block is open. There is a possibility that old, pre-1991 versions of the block are still in use.

We have subsequently received a third-party notice which gives the following additional information and guidance for its own operations which members may find of use:

The company involved has banned the use at its worksites of the McKissick N419 Snatch block in figure A, whose design allowed for interchangeable head fittings as depicted in figure A.

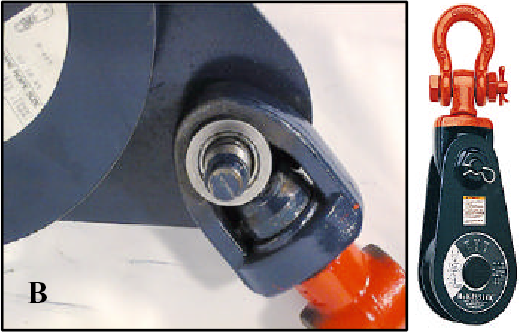

The Crosby Group Inc. (manufacturer of the McKissick N419) has since 1991 added features to retain the head fitting regardless of the position of the block (Figure B). Both snatch blocks carry the same name, but production of the snatch block in figure A was discontinued in 1991.

As a result the company will not use the ‘old style’ snatch block (figure A) in its operations.

The company instigated the following actions for all of its installations:

- Check all snatch blocks on installations, and remove from service the ‘old style’ McKissick N419 snatch block;

- For applications where this type of device is required, ensure that the current Mckissick N419 snatch block is used (Figure B);

- Make sure that all inventory lists of loose lifting appliances are updated with necessary information

Safety Event

Published: 1 December 2003

Download: IMCA SF 13/03

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.