Lost time injury (LTI): Hand injury

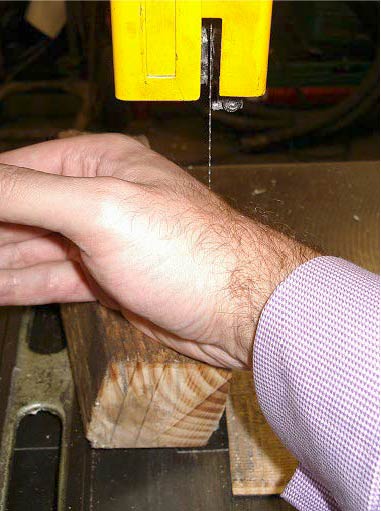

A member has reported an incident in which a worker sustained a serious injury to his right hand. The incident occurred in an onshore mechanical workshop. The injured person was attempting to cut a small block of wood down to size to use as a spacer. Whilst using the mechanical workshop vertical band-saw his hand came into contact with the moving blade, causing a serious laceration to the back of the hand and resulting in tendon damage.

Our member’s investigation revealed the following:

- Immediate causes:

- The wood split during cutting due to the application of excessive force to the wood, which was caused by excessive wear on the blade and the incorrect positioning of the wood;

- A ‘Push stick’ was not used;

- An adjustable guard was not used.

- Root causes:

- Lack of hazard awareness/complacency – the injured person did not identify using the machine as a hazard and did not use the available safety guards and processes whilst operating the saw;

- Uncondoned behaviour/violation – the injured person identified a fault with the saw but continued to operate it without reporting the fault.

Our member took the following actions:

- Workshop/Yard Induction form to be reviewed and updated to include specific mention of Safety Observation Card requirements, Stop the Job requirements and section relating to machinery operation and competence;

- Review of induction frequency requirements and inclusion into site management procedures;

- Prepare and issue pre-use checklists for each machine with requirements for inspection prior to use, following use and reporting requirements where faults have been identified;

- Implement locking e-stop system with controlled key access to prevent unauthorised use;

- Update risk assessment with lessons learned from incident investigation where pertinent.

Safety Event

Published: 26 October 2012

Download: IMCA SF 11/12

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.