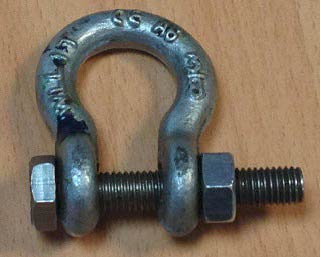

Near-miss: Shackle configuration

A member has reported finding shackles used for lifting equipment in an unsafe condition. A third-party lifting inspector was re-certifying lifting equipment when a 1 ton lifting shackle was discovered which had lost its pin, and the missing pin had been replaced with a standard bolt and nut which was not certified for lifting operations.

Additionally, the shackle was found to be pinched due to excessive pressure being applied when tightening the nut due to the bolt having thread along its entire length. It was not clear whether or not this shackle had been used for lifting but the potential for injury to personnel or damage to assets was high.

The following lessons were learnt:

- Lifting equipment should be fit for purpose and certified by a competent authority for use;

- Replacement or repair of lifting equipment invalidates the certification;

- Lifting equipment should be reviewed regularly for non-compliance and any non-compliant items taken out of service;

- Where damage is evident or pins/bolts are missing, the equipment should be removed from service and either destroyed or new parts ordered;

- If new parts are ordered, the lifting equipment should be re-tested with a certificate issued prior to return to service;

- Lifting equipment should follow the current colour coding;

- Lifting equipment colour codes should be well communicated and displayed;

- Identifying and reporting faults in lifting equipment is a regulatory requirement in many places and should be seen as a first line of defence.

Members may also refer to Guidelines for lifting operations.

Safety Event

Published: 18 January 2013

Download: IMCA SF 01/13

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.