Ruptured hydraulic hoses

A member has reported an incident involving the rupturing of a pair of hydraulic hoses on a vessel crane. The incident occurred during a port call when the mid-ship crane was being used to move packaging from the main reel area to the deck. A hydraulic hose ruptured and oil was spilt to the main deck below. The majority of the hydraulic oil (20 litres) landed on the deck but approximately 500 ml of oil went into the sea.

An ‘all stop’ was initiated and the spill on deck was immediately cleared up using a Ship Oil Pollution Emergency Plan (SOPEP) kit. The following day another hose ruptured in a similar location and all oil was contained on deck. The relevant authorities were notified.

Our member’s investigation revealed the following:

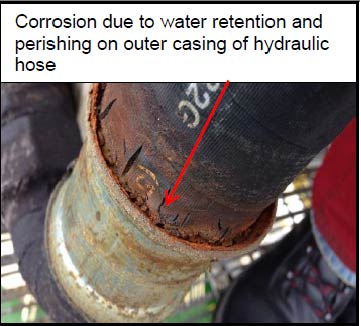

- The ruptured hoses were badly corroded;

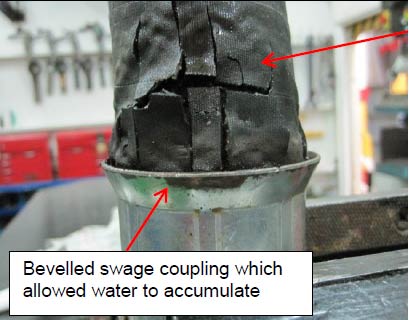

- The design or assembly of the hydraulic fittings had allowed water to accumulate around the neck of the fittings;

- The collection of water had eroded parts of the hoses resulting in the ruptures;

- Other hoses onboard were found to be in a similar state;

- The inspection of the vessel crane hydraulic hoses was conducted by vessel crew and a third-party contractor. The most recent inspection had taken place four months previous to the incidents occurring. It was found the crew and the third party inspection team had not removed the ‘denso’ tape wrapped around the hose fittings, thus the corrosion was not visible;

- It was apparen’t that the corrosion on the hoses had occurred over a long period of time and this should have been spotted by the inspection by vessel crew and contractor, and noted in their report.

Our member immediately replaced the badly corroded hoses and undertook an investigation to ascertain why the contractor and crew had not identified the corrosion during the previous inspection. It was found the ‘denso’ tape was not removed from hose fittings during these inspections and as a result the corrosion was not visible. Removal of ‘denso’ tape from hose fittings is now required for all future inspections.

Members may wish to refer to the following similar incidents (key words: hydraulic, hose, rupture):

Safety Event

Published: 3 October 2014

Download: IMCA SF 16/14

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.