Serious injury during crane operations

A member has reported a serious injury that occurred during crane operations on a third party vessel. The vessel had been released from towing a flexible riser and the tow-wire had been recovered to the vessel deck. The crew was removing flotation and a soft strop extension from the tow wire using the port-side Palfinger crane.

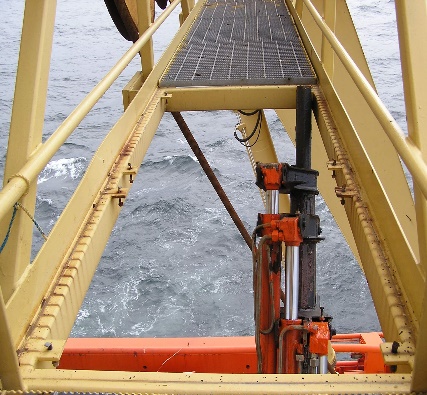

The crane operator, controlling the crane using the remote control flying lead, was repositioning the crane for the next operation when he drove the head of the boom up and into the grating floor of the A-frame walkway, 14 metres above the main deck. The grating came loose due to the force and fell. The crane operator, who was standing directly underneath the grating, was hit on the head and then the left foot by the falling grating, estimated to weigh between 10-12 kg.

Although the injured person suffered four broken bones in his left foot, a wound to his left elbow and superficial injuries to his head (cut/bruising), the company concerned has noted that the potential for a fatality to have occurred in this incident cannot be over-emphasised.

The company made the following observations as regards the likely immediate causes of the accident:

- Lack of care and attention – This was a ‘routine’ operation performed by the most experienced crane operator on the vessel. Checks of the height of the crane boom in relation to overhead hazards should have been carried out prior to any crane movement;

- Incorrect working position – The crane operator had failed to stand in a safe working position and was directly under the hazard. As a result of incorrect working position, he would have been unable to judge the height of the crane boom in relation to the A-frame walkway;

- Incorrect PPE – The injured person was not wearing safety boots but was in fact wearing backless safety shoes (clogs).

The company has made the following notes and suggestions:

- During ‘routine’ work there is the possibility for complacency to arise, so treat every task as if it is a new task;

- Examine your working position before starting work and ensure you assume the safest position for the task;

Consider industry best practice for lifting, requiring three personnel to be involved in every lift – crane operator, banksman and load handler.

Safety Event

Published: 31 July 2005

Download: IMCA SF 09/05

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.