Thermal tunnel buoyancy when deployed subsea

A member has reported an incident in which buoyancy problems were encountered with equipment being deployed subsea. During light subsea construction operations conducted from a DSV, there was a requirement to deploy two ‘thermal tunnels’ as a barrier between an existing pipeline and a new umbilical being laid. When the thermal tunnel was deployed it became obvious to the crew that despite it weighing 515kg in air it would not penetrate the splash zone. The thermal tunnel was too buoyant and would not sink.

After investigation it was discovered that the manufacturer’s buoyancy calculations were incorrect; these were checked by the on-board engineering team. These thermal tunnels are manufactured for subsea use without appropriate quality checks being carried out by the manufacturer.

Our member learnt that this could have been prevented had there been a sea water wet trial performed by the manufacturer before delivery to the client, or if there had been independent verification of the mass, volume, and displacement, and of the buoyancy calculations. This finding was passed back to the manufacturer. Our member noted that for all items deployed subsea the upward force or buoyancy should be independently verified by an engineer.

The following actions were taken:

- Consulted with manufacturer to ensure that these findings were passed back appropriately;

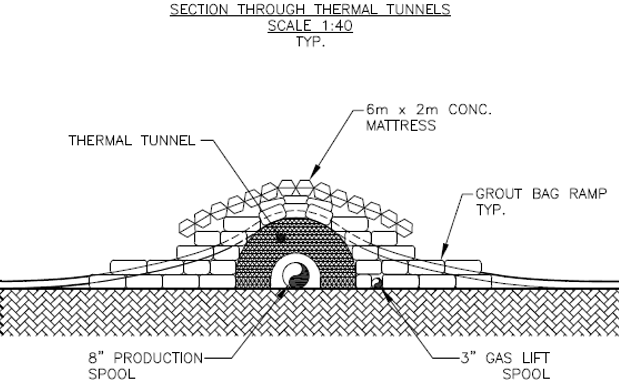

- Generated a management of change process and applied a temporary solution, whereby additional weight was added to the thermal tunnel to assist with the installation. The thermal tunnel was successfully installed in position and covered with a concrete mattress;

- Ensured that all future deployments of thermal tunnels would have manufacturers’ certification of wet test, or independent validation of mass detailing suitability for subsea use.

It was noted that a remaining risk was that if the concrete mattress was subsequently removed and the weight fixings in the meantime had perished, the buoyancy issue would be realised again. This is an unknown but should be taken into consideration in future. members using thermal tunnels may wish to review their procedures to mitigate the risk of tunnels floating to the surface, as this is a potential hazard to both divers and vessels.

Safety Event

Published: 28 August 2015

Download: IMCA SF 12/15

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.