Dropped object injury: Equipment shifted when it was incorrectly unsecured

What happened?

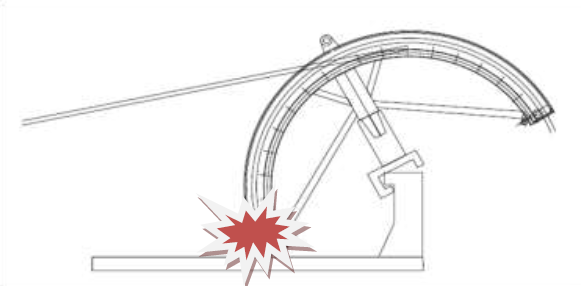

On a cable laying vessel, a cable quadrant had been rigged on the bulwarks, seated in a pedestal mounting and secured via lashings on the outboard side. Normal operations required the deck crane to be secured and taking the quadrant’s weight before the securing was removed. However, during this incident, the securing was removed before the deck crane was secured.

As a result of being unsecured, movement in the cable caused the quadrant to topple and fall to the deck, striking a crewman in the leg. The incident caused minor grazing to the leg and soreness. First aid was administered and the crewman returned to work for the next watch. The incident could easily have resulted in more serious or permanent injuries. Our member treated as a high potential near miss.

What were the causes of the incident?

- Failure to correctly follow procedure and secure the deck crane before the lashing were removed;

- Failure to clearly identify who was in charge;

- Reliance on control measures (outboard securings) that provided only a single point of failure.

What lessons were learnt?

- Communication & Control – it is essential to identify who is charge before starting lifting operations. This avoids confusion or miscommunication, and should be highlighted during Toolbox Talks;

- Control measures should be reviewed to identify potential improvements. Although certain control measures may have worked in the past, we should always review them to see if improvements can be made. In this example, fixing the pedestal mounting itself would have reduced the risk of toppling when the outboard securing was removed – or even if the securing had failed during operations;

- All crew should be aware of the control measures that are in place, where to find them, and how to maintain them during operations. Again, this should be done by reviewing job safety assessment (JSA) during the Toolbox Talk and by conducting site walk-about before beginning.

Actions

- The pedestal mounting will be fitted with tipped bolts to secure it directly to the bulwark in future;

- Management will designate a specific person in charge for deck operations.

Members may wish to refer to the following incidents:

Safety Event

Published: 22 May 2017

Download: IMCA SF 11/17

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.