Hand injury from falling object during lifting operations

What happened

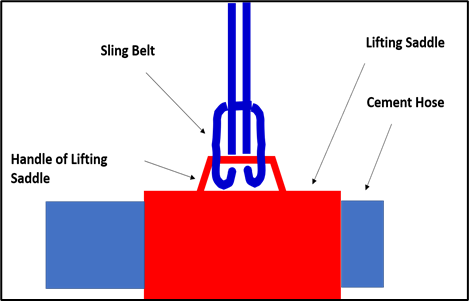

A lifting saddle broke, causing a hose to swing and hit a crewman, causing an injury to his hand. The incident occurred at completion of cement pumping between a vessel and a rig. During recovery of the cement hose, the saddle handle broke, and this caused the hose to swing and hit the AB, who at that moment was giving a signal to the crane operator. He was not under the hose or the load, but was approximately 10 meters away. Part of the hose was still in the water. He was in the line of fire when the hose swung in his direction and he braced using his forearm, resulting in an injury.

What were the causes?

- The lifting saddle broke where the sling was incorrectly attached;

- The hose was lowered from the rig to the vessel deck only slinging the handle of the saddle and not passing it around the hose;

- The deck crew noticed this incorrect lifting arrangement but did not stop to correct or change it, and give the instruction to pick up.

Lessons learned

- Stop Work Authority should be exercised if incorrect procedures and unsafe conditions are noticed, particularly during lifting operations;

- Thorough and regular inspection of all loose lifting equipment.

Members may wish to refer to:

- IMCA HSSE 019 Guidelines for lifting operations

- Short videos – Are YOU prepared to work safely?

- Line of fire LTI: Finger injury during lifting operations

- Uncontrolled movement of crane block and pennant during lifting operations at sea

- Serious LTI – deck crew member struck by termination head/flexible

- High potential dropped objects from wind turbine Nacelle crane

Safety Event

Published: 16 April 2021

Download: IMCA SF 11/21

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.