BSEE: Unsafe crane working practices result in injury

The United States Bureau of Safety and Environmental Enforcement (BSEE) has published Safety Alert #446 relating to an injury caused by unsafe crane working practices.

What happened

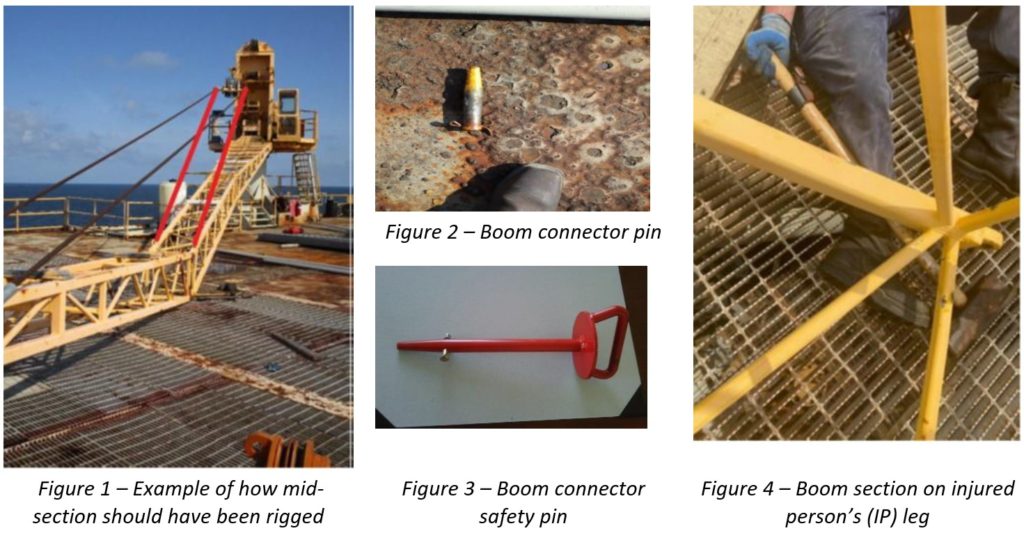

A lead mechanic suffered a severe leg injury while performing a boom tip changeout on an offshore pedestal crane. He and his assistant deviated from the planned scope of work, failed to rig up the mid-section to the bridle (Figure 1) prior to removing the mid-section to boom tip connector pins (Figure 2), and failed to use boom connector safety pins (Figure 3). After removing the bottom right pin, both employees assumed the bottom left pin would be difficult to remove since it was bearing the weight of the boom section. When the lead mechanic struck the remaining connector pin, it unexpectedly ejected, causing the boom to drop and pinning his leg against a sledgehammer and grating (Figure 4), fracturing his tibia.

Facility personnel used a pallet jack, a piece of two-inch pipe, and a two-by-four piece of wood to lift the boom tip and pull the lead mechanic from under the boom tip and then administered appropriate first aid.

What went right: The response of the facility personnel was critical in providing lifesaving interventions until treatment could be provided at the hospital on shore.

What went wrong

The company’s incident investigation found that the root causes were:

- The Job Safety Analysis (JSA) was only completed by one employee and did not include rigging up the mid-section to the bridle prior to removing pins or the use of safety boom connector pins. In addition, the lead mechanic signed off on the JSA without actually reviewing it;

- There was no requirement for onshore management or the crew to review the JSA before starting work.

Recommendations

- Review of policies and procedures, ensuring compliance with the JSA requirements;

- Reinforcing the use of Stop Work Authority particularly when the scope of work changes;

- Understanding the importance of staying out of the line of fire when working near heavy equipment and considering all possible pinch points when walking down the job;

- Verifying all safety equipment is available and in place before the job starts;

- Providing specific written procedures to individuals disassembling cranes;

- Ensure that you do actually review the paperwork, risk assessment, JSA etc before you sign off on it and before you start the job!!

- Ensuring specialized contractors create and maintain written procedures and checklists for common jobs;

- Conducting drills based on realistic injury and first-aid scenarios and inspect medical supplies and kits at the facility level.

Members may wish to refer to:

Safety Event

Published: 10 November 2022

Download: IMCA SF 25/22

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.