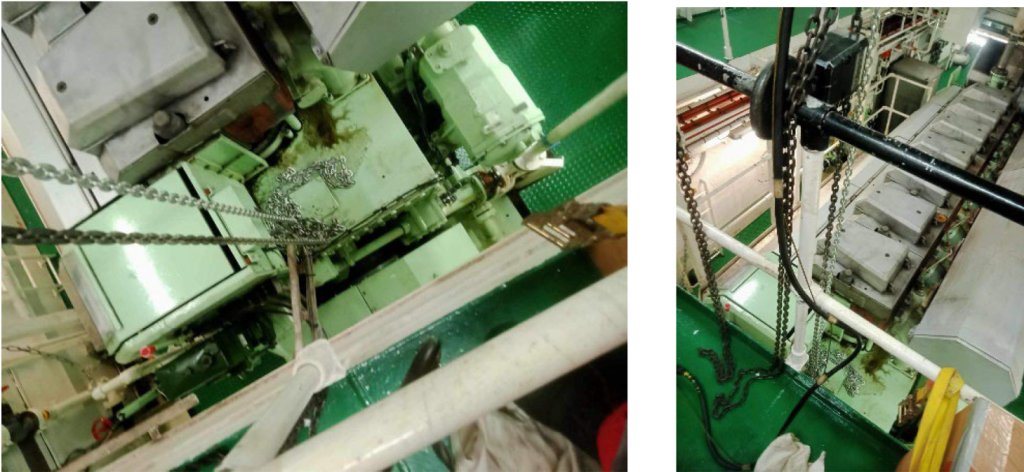

Chain hoist paid out unsupervised near running main engine

What happened?

An electric chain hoist on the beam above one of the main engines in a vessel, was left unattended after use. The chain hook paid out and coiled the chain onto the running main engine close to the generator drive shaft. The incident occurred when the chain hoist was being used to lower spare parts required for maintenance in the engine room. Two lifts took place above the running main engine. After their completion, the chain block was lifted into its highest position.

Later on, during routine rounds, the motorman observed the hoist’s chain with hook to have “paid out” fully and created a dangerous condition near to main engine no.3. The chain was made safe and then removed from service for inspection.

What went wrong

- The push button for “pay-out” on the pendant controller for the electric winch, was found to be defective, resulting in hoist being given a continuous payout command;

- The operator of the hoist was aware that the chain continued to pay out after push button was released in the first instance, but after repeated operations of the button assumed the intermittently ‘sticky’ button had been freed and that the equipment was safe for use;

- The emergency stop button was not engaged after use which enabled the faulty button to allow the hoist to continue uncontrolled pay out;

- The hoist, although paid in, was not stowed and secured as per the routine working practice onboard;

- As a result of the continuous payout operation, the motor was found to be burnt out and will require to be replaced.

Actions

- Ensure crew are familiar with original equipment manufacturer (OEM) operator manuals for all hoist equipment before use;

- Review control function of hoists and where no designated isolation switch is in place, determine a safe, and practical means of safe isolation.

- Ensure visual and function tests for lifting equipment are conducted with defects/ damage corrected before use.

- Review whether hoists can be safely used parallel to or in close proximity to running machinery.

- Review frequency of planned maintenance for electrically driven, operated and controlled lifting hoists, to minimize risk of control functions degrading due to infrequent usage, and to ensure an annual function test is completed.

Members may wish to refer to:

Safety Event

Published: 9 January 2024

Download: IMCA SF 01/24

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.