Rigging failure – clump weight dropped to seabed

What happened?

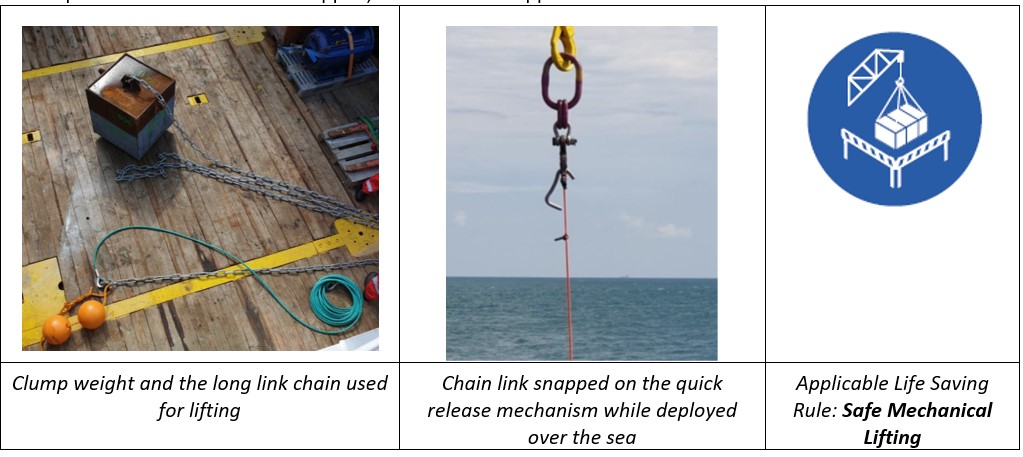

A clump weight used for anchoring a weather buoy was being deployed over the sea when the long link chain attached to the vessel crane hook failed resulting in the clump weight dropping to the seabed.

The 2.6t clump weight was the anchor component of a mooring arrangement for the weather buoy. The load was rigged using a supplied mooring arrangement, which followed the manufacturer’s drawing in the weather buoy manual. Instead of a 450kg weight it was decided to use the 2.6 tonne clump weight already available and which had been shipped to the location for deployment. A service specialist prepared a deployment procedure which was discussed with those involved in the task. Shortly after the load was submerged in the sea the chain link attached to the quick-release mechanism snapped, and the load dropped to the seabed in an uncontrolled manner.

The findings revealed:

- The rigging failed because a larger clump weight (2.6t) was selected than the design allowed for (450kg). This decision was based on previous experience where the standard weight (450kg) did not adequately secure the weather buoy;

- The design and installation procedure were not revised to accommodate the heavier clump weight;

- The chain selected was not suitable for lifting. Declaration of conformity by the chain manufacturer confirmed that the working load limit was “2.5 Tonne Not for lifting”.

Actions

- All planned deviations from procedures should be subject to a formal Management of Change (MoC) process, the risk of the change adequately assessed and the change authorised by a competent person before the work proceeds;

- Reinforce to the riggers and personnel involved in lifting operations:

- The need for thorough lift planning, and,

- That they make a thorough check that lift rigging is certified, fit for purpose and appropriate for that specific lift.

Members may wish to refer to

- SEL 001 Guidelines for management of change

- SEL 019 Guidelines for lifting operations

- Short IMCA videos “Are you prepared to work safely?”:Lifting operations Lifting equipment

- Near miss: Dropped taut wire clump weight

- Weight dropped to the seabed narrowly missing diving bell

- Near miss: Single wire strand protruded from original lay

Safety Event

Published: 6 December 2020

Download: IMCA SF 33/20

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.